|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

| Engineers in Rushden, H E Packwood, January 1988 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Engineers in Rushden

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The following notes are that I remember; if there are any mistakes please accept my apologies. Messrs. J.S. Clipson, Church Street, Rushden. Phone. No. R1. (Now M. Neville's Estate Agents) Earliest agent for Gas Engines and all tools used in the Boot and Shoe Trade. Wood pulleys for line shafting. All types of thread, needles, pincers, knives etc. At this period the JONES sewing machines were very good, they would machine heavy leather uppers. Personnel :- Apprentices :- Central Machinery Co. Victoria Road, Rushden. Owned by Mr. Ernest Pack and son Cyril. Main agents for Gas Engines and line shafting, most work was engine maintenance. Rushden Engineering Co. High St. South, Rushden. (now occupied by Central Electric Co.) Owned by Mr. Fred Hawkes’ brother and Mr. Bob Camel. They vacated the premises and the work was carried on by Mr. Corby in Mr. Lockie's workshop. [Fitzwilliam St] Whipple Starter Co., Sartoris Road, Rushden. Mr. Whipple had 2 inventions nationally approved. 1. A motor windscreen washer which consisted of a roller of rubber that gently 2. An electric bus starter:- this was made for buses that were started by a handle On his death the business was transferred to Mr. H.S. Wright and then to Mr. Sutton.

Standard Rotary Rushden. At the turn of the century the Boot and Shoe Manufacturers realised that they must get things up to date and make or buy their own machinery. A building at the bottom of College Street was built by a group of manufacturers, opposite Alfred Street School now the site for the Budgen Supermarket. To get the skilled labour required it was decided to advertise in a trade union journal. A manager who was also a draughtsman was chosen - Mr. Pickard and he engaged the workers. The following are the men engaged as I remember them :-

Local Men engaged :-

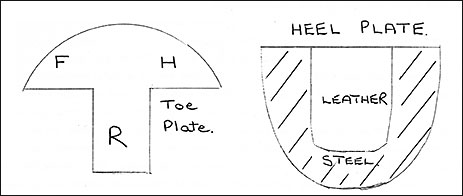

When the skilled workers arrived in Rushden they brought with them all the tools, lathes, milling machines and they also brought their own Trade Union, the A.E.U. together with the Birmingham District Rate which was 2/- higher than the Northampton Rate. When the 1914 war broke out the work was all for munitions. At the end of the war short time was being worked, Gimson Engineering took over the company the workers still working short time. Eventually the Gimson Co. was taken over by British United Shoe Machinery Co. and the Standard Rotary was closed. Work was offered to the employees at Leicester, C. Pearson and R. Eagles taking the offer. W. Lockie & Son, Newton Road, Rushden. Lockie's had a small workshop at the back of Newton Road (Ebeneezer Terrace). Now the third generation is working in a small factory in Fitzwilliam Street. Mr. Lockie made all kinds of sheet metal tubes etc. to take away the trimmings of leather in shoe factories. Hawkes Ltd., Portland Road, Rushden. Mr. F. Hawkes was the inventor of the Army Toe Plates for the 1914 - 1918 war. He also reconditioned machinery for the Boot and Shoe trade and had customers all over the world.

The Wilson Gas Meter Co., Station Road, Rushden. The company was bombed out of Coventry and came to a small factory in Station Road in 1943. The girls working there had to strip a thick layer of sponge rubber from the outside of Aeroplane fuel tanks this rubber prevented bullets from entering the tanks. The tanks were cleaned and repaired before being returned to the R.A.F. The factory was closed down at the end of the war. A.J. Ginns, High Street South, Rushden. Blacksmiths

Cox Engineers, Lime Street, Rushden. Makers of the COX SLUGGER for putting on leather top pieces round about 1919. Employee:- Chip Randall on maintenance. Covallen Engineering Co., Lawton Road, Rushden. In 1921 Mr. H. Coggins took over this firm from Armitage & Robinson, Manager A. Tilley, makers of sewerage parts and other heavy machines. During the war years they made turrets for the Tanks. Mr. Coggins was one of the first employers to engage a full time welder, Mr. F. Chapman of Newmarket also a wooden pattern maker Mr. Billing. Apprentices to the trade were bound for 5 years, the firm and the parents signed over a sixpenny stamp to make it legal. When an apprentice had served his 5 years he would then be known as a journeyman until he was 21. After the war the firm continued to make sewerage, farm parts and other cast iron equipment. Work became short around 1977 and Mr. Alex Coggins who had taken over on the death of his father sold out the firm to Mr. MacCorkadale, and Mr. A. Coggins moved to Wellingborough where he owned The Wilfley Mining Machinery Co. Norris & Son. Previously owned Safford, Wellingborough Road. Norris began in a small way making machines for the Leather Industry. I think I am right in stating that Norris were the first firm to fit a gearbox to a leather drum instead of being driven from line shafting. At the outbreak of the 1939 war Norris were commissioned to recondition lathes from A. Herbert’s of Coventry, this was a totally different job from currying machines. At the end of the war a partner joined the firm - Mr. J. Orme and all the dies etc. were made for the Rosebud Doll factory at Raunds. Mr. Orme then left to start on his own taking a number of skilled men with him and made machines for the plastic industry. The skilled men who moved were:- Mr. G. Longland: Mr. R. Walker: and Mr. E. Houghton. Their work consisted mainly of cones for road works and anything connected with the plastic industry. They still have a factory in Duck Street and one in Park Road. I think that Smiths Containers Ltd was started from these factories. A small factory at the bottom of College St was owned by 2 brothers named Perkins. This factory contained 2 Power Die cutting machines for making brass screwing wire that was used to reinforce the soles of heavy boots, this factory closed down about 1924? At the outbreak of the war 1939 the above factory was re-opened by Horace Wills and Cyril Johnson making munitions and was called The Sound Engineering Co. Cyril Johnson bought out Horace Wills and then moved to Hove Road building most of it himself. Cyril Johnson was very clever but unfortunately died about 26 years ago and the factory was sold to Wicksteed’s Engineering Co of Kettering. C.W.S. Boot Factory, Rectory Road, Rushden. I was employed by the C.W.S. in August 1920. The new offices were being built by direct labour - Clerk of the Works - Mr. Metcalf. Employees :-

The C.W.S. at this time built a Corset factory in Wellingborough, also a Boot Factory in Northampton to which I was transferred in 1927 returning to Rushden in 1934. The C.W.S. and other factories had their own Gas Plants making gas for their own engines. Mr. Carl Bailey who workes for C. Horrell’s was unfortunately asphyxiated while repairing the retorts in 1921. At the C.W.S. a steam whistle was blown to commence and finish work, this was stopped at the outbreak of the war 1939. Another phase of Rushden history was the building of the Local Electric Light Co. in Shirley Road. Mr. Sammy Scragg and Mr. Sam Bailey arrived in Rushden in 1903 being qualified to do the wiring necessary to wire the factories. The wiring used was known as capping and casing, the wire being in wood casing. Mr. Sam Bailey on finishing the wiring etc at B. Denton’s, High Street (now demolished) was offered the position of engineer, which he accepted. This entailed looking after the Gas plant etc. and engines and the small tannery they owned in Rectory Road. Mr. Sam Scragg then started the Central Electric Co. in High Street South, he soon had plenty of work especially Government contracts. On his death the business was transferred to W. Timson and W. Ekins and is now owned by W. Timson junior. N.B. These notes are not to be used by yourself or a third party for commercial interest or public gain without the knowledge and permission of:- Mr. Herbert Edward Packwood, Queen Street, RUSHDEN, Northants. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||