|

Rushden Echo & Argus, 16th January 1948, transcribed by Kay Collins

A Growing Industry – Rushden Helps Atomic March – Modern Machines

A machine which will enable coal to be recovered from “waste” material at the rate of three tons an hour has just been built at a Rushden works, where the engineers are also making machines for atomic energy plant.

|

|

Leading electric welder at the works Mr. F. Chapman, of Moor Road, Rushden, is welding a component for a machine.

|

On the verge of a 50 per cent extension, the Covallen Engineering Co. is building up a very useful secondary industry for the town—one which already brings into Rushden a lot of skilled workers from the neighbouring towns and villages.

The coal reclaiming machine stood ready for dispatch when we saw it in the assembly shop. A tank-like monster of 24 tons, painted grey externally like a warship, it stretches to a length of 56 feet, rises to 8ft. 9in. and has a width of 7ft. 3in.

It is an assembly of floatation cells and actually an outsize edition of the plant used for the recovery of gold.

The process employed is suitable for the recovery of all metals with the possible exception of tin, and is being used in this country on fluorspar, which is employed in steel production.

When crude ores are placed in the floatation cell they come under the influence of suitable reagents which separate them and the metal is floated to the surface of the liquid in a comparatively pure state, in exactly the same way coal dust can be collected at a rate which is going to help the fuel problem.

One of the oldest companies of mining machinery designers in the world, the Wilfley Mining Machine Co. Ltd., of London, is owned by Covallen, who make for it gravity concentration machines for extracting gold, silver, tine, lead, and other metals from crude ore.

Atomic Machines

|

|

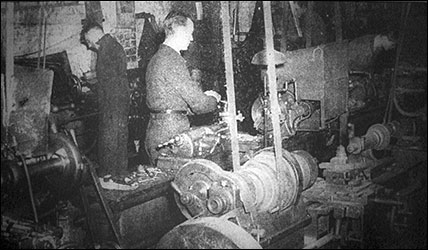

A section of the machine room at the Covallen Engineering Works, showing man at work on lathes, turning machine parts.

|

The atomic machines that Rushden is making will be used in the pursuit of medical science. One of the largest current contracts is for this purpose.

For one client the company is making a large variety of machines which to the general public will appear to have peculiar names.

Take clariflocculators. These are used abroad for production in connection with filtration plant of water suitable for domestic and industrial purposes from rivers laden with impurities.

Five of these machines have been provided for use in the Middle East oil refinery area. They are used in this country also, and one unit recently ordered will provide boiler feed water at a power station scheduled to be in operation early in 1950. They are also used widely in Britain for water and sewage purification.

Impeller dissolvers and mixers constitute a vast range of equipment with an equally wide field of application. They help to produce rayon fibre, sugar, fertilisers, lubricating oils and even toilet preparations such as toothpaste. Collieries and steelworks use them also.

Thickeners and classifiers also serve a great range of industries. Orders now in hand will assist the production of coal, fertilisers, lubrication oils, caustic soda, paper, steel, iron, gold, copper, foodstuffs and general chemicals.

Other orders—all associated with essential industries at home and abroad—are for plungers, clarifiers, digesters, detritors, premixers, agitators, pumps, hydrotreators and sizers.

It is equipment of this type that will be used in connection with atomic energy. Much of the equipment listed is used for the disposal of trade waste and sewage and also for the prevention of river pollution by poisonous effluents from factories. [continues on page 16 of the paper]

|