|

|||

| The Rushden Echo & Argus, 21st February 1930, transcribed by Jim Hollis. | |||

|

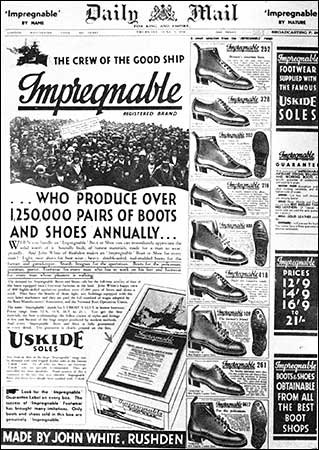

Growth of a Rushden Boot Firm

|

|||

|

|

|||

|

Marvels of Organisation - How Waste Is Cut Out

|

|||

|

“Speaking of the boot trade generally – excluding Mr. John White’s factories . . . . . . . .” said a local resident to a “Rushden Echo and Argus” representative, and the remark struck our reporter as rather funny, yet significant. After a visit round Mr. White’s factories this week, under the supervision of the chief, our representative gained the impression that the boot trade is carried on in those works. But the speaker held the reasonable view that Mr. White’s organisation and output are exceptional and a thing apart when the state of the trade generally is considered. Yet Mr. White started only as recently as 1918. There is no waste worth considering in any of the factories. That in Manton-road has undergone wonderful transformation under Mr. White’s ownership. A large store shed has been erected in one part of what was formerly an almost disused yard, and in another part, fronting Grove-street, is a garage for the company’s – Messrs. John White (Impregnable Boots) Ltd. – huge delivery vans. Within the factory there is the minimum of carrying materials and no waste floor space. Clickers being on the top, the succeeding operations follow on the floors below, the finished product being on the ground floor ready for packing in the vans. Speed Without Rushing Standing anywhere in the big area of the making and finishing departments of the factory in Newton-road – the chief and most scientifically organised of the firm’s three factories – one is almost overwhelmed at the sight of multitudinous machine operations and the roar which they produce. Also one is struck with the fact that, enormous as is the output, there is nothing rushed or frantic in the movements of the operators. Scores of thousands of boots and shoes on racks fill most of the spaces between countless machines, and as there is no waste floor space the racks need to be moved only a few inches from one operator to another. Always having an eye to the health of the operatives, Mr. White has taken special pains over the clicking department. From such sections of boot factories in times past have come the worst records of tuberculosis in the industry. To obviate that in his own works, Mr. White has had the clickers’ department specially large, light and airy. The maximum possible of cleanliness is also insisted upon for the sake of health and appearance. This is particularly noticeable in the closing department (formerly the premises of the Rushden Heel Company). The general arrangement of machines and workers here is ideal. Incidentally, Mr. White showed our representative a clever invention from the British United Shoe Co., which he has on trial. To the uninitiated it might be thought that the narrow edge of leather turned under for “beading” the toe-cap was an absolutely negligible item. The fact is, however, that to avoid that waste means the saving of one cap in eight or so. The principle whereby the new machine does the work without the wastage is the application to the raw edge of electrically controlled heat, which gives an appearance equal to that of beading, but does not use up the width of leather. Two Moving Circuits The same methodical working is at once clear to the observer in the old “Advance” Works (opposite the Waverly Hotel). In the Manton-road factory there is an output of some 5,000 pairs weekly, these being mainly of the heavy type of men’s wear – strong field boots, and so on. In the Newton-road works welted boots are made in one wing, the staple welting machines being used very successfully. The machine sewn and allied department (above and alongside which the welted work floor is raised a few feet) reaches to the bottom extremity of the factory. The product of each passes round the room and reaches the one outlet provided for both. Thus there are two circuits complementary to each other. This is in accordance with up-to-date factory organisation. A word has been said about the care of the health of the operatives in the Impregnable Boot Works. Another great feature is the rate of wages. Over 99 per cent. of the operatives are members of the National Union of Boot and Shoe Operatives, but they do not have to “enforce” the union minima, because the firm pays over those minima in every case, varying from 4/- extra to £3. “The boot trade – excluding Mr. John White’s,” is one of the highest compliments which the writer has heard of Mr. White. The remark was made quite unconsciously of needing explanation. The boot trade is understood to be that part of the trade which has seemed to follow a course which many could foretell, but that part of it which Mr. White provides for the town has gone on increasing in a way that none could have seen or believed a few years ago. We gathered that it has not by any means reached the noon of its era.

|

|||