|

|

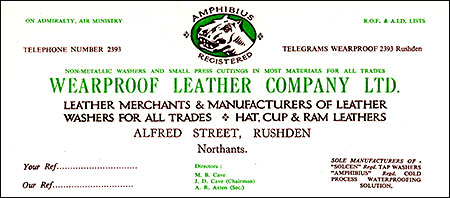

1933 Letterhead when R P Cave was the proprietor

|

| The Wearproof Leather Co. was started in the 1880s by Amos Cave, son of John Cave, in what had been the family's coachhouse. The stables were the workshop, the hayloft the leather store and the saddle room was the office. |

Rushden Echo and Argus, 18th February 1898, transcribed by Kay Collins

COUNTY COURT CASE—The action brought by the Waterproof Leather Co. (Messrs. Cave), Rushden, against C. Bailey, Finedon, for leather supplied, came on once more at the County Court at Wellingborough on Monday before Judge Snagge. Mr. F. J. Simpson (Simpson and Mason), who represented plaintiffs, said the case had been adjourned from time to time for the appearance of Mrs. Bailey. He had that morning received a letter from Mrs. Bailey, but he feared she was trifling with the Court.—His Honour, having read the letter, said he would either grant another adjournment or would order a non-suit.—At Mr. Simpson's request a non-suit was entered.—Mr. Simpson: What about our costs?—His Honour said he could not allow plaintiffs' costs but would see they did not have to pay defendant's costs. |

|

| 1910 advert in Phillipson's Directory |

|

In 1912 the company was in financial trouble.

It survived and was sold - from Amos Cave's obituary in 1923 we know:-

.... the Wearproof Leather Company in Alfred-street (now in the hands of Mr. R. P. Cave).

|

|

Rushden Echo, 20th December 1912

Sale—On Monday and Tuesday Messrs. Hamilton, Palmer, and Co. offered by auction the stock-in-trade, plant, and machinery of Mr. Amos Cave. The boots made extraordinary prices. The cut stuff and leather sold very well, and the machinery fetched a fair price. Among other items were a treeing machine £10/10/0; Standard Rotary welt sewer £85 and a stitcher £75. Two Cox’s slugging machines realised £17 each; a small press £8; Julian rounder £9/15/0; Gimson’s jumper press £45; Giant heel compressor £21; Gimson’s screwer £75; Perfecta tacker £7/10/; Blake sewer £14/10/0; Bed laster £17. The Rushden Wear and Waterproof Leather Co. was sold as a going concern at £55.

|

| Rushden Echo, 12th October 1917, transcribed by Gill Hollis

A Nasty accident occurred yesterday at the factory of the Wearproof Leather Co., to a little lad named Chettle, son of Mr. Chettle, of Duck-street. The boy was putting welts through a splitting machine when, it is thought, for some reason or other he must have lifted the guard, with the result that he got his left hand in the rollers, the hand being badly crushed. Mr. Amos Cave, the principal of the firm, at once went to the lad’s assistance, and extricated his hand from the machinery. He was then taken to Dr. Owen’s surgery and from thence by motor-car to Northampton Infirmary, where he is making satisfactory progress. [see index of shoe factory accidents]

|

Early in the 1930s Don Winters joined the company and worked with Bill Cave. Later William Knott also joined the company. All three were keen scouts.

This part of the business only made the washers and small items. Don took over when Bill Cave retired (he died aged 80 in 1955).

The office, formerly the saddle room, was at the top of the yard, with a large open workshop on the ground floor of the rest of the building. Above the office was the old hay loft.

There were press knives of all sizes, presses, a skiver, and punches. A small stove stood in the centre with a kettle, and they would burn the off-cuts along with the coke or bits of wood, nothing was wasted. A large tank at the end of the room was for soaking the washers overnight in a waterproofing solution.

Large off-cuts of leather were bought from the local factories and some suede. Suede needed to be ironed before it was used, and later Don would take this home for his daughter Marion to iron, and so earn her pocket money!

If the leather was too thick it would be passed through the skiver or strimmer first. That was a very dusty job, long before health safety. Five presses were driven by overhead belts and the tap washers were punched out of the leather.

The washers were then threaded onto string, counted into dozens for each order, and then hung in the tank overnight, and next day sent off to the complete the order.

Other small items such as belts were also made by the company. At sometime the company moved to part of 23 York Road, but probably not until at least 1980.

|

The company made washers for engineering, gas trades and water board, and straps for machinery and decoration.

|

|

|

Gaskets, seals, washers, straps, slitting, leather, cups, contract cutting & samples found in 2005

|

|

|

Two letterheadings - c1920 & below 1934

|

|

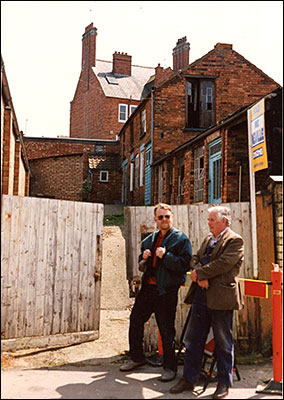

Survey of a factory later occupied by Wearproof Ltd.

For a photo album of the factory click here Ebooks and scroll down for 23 York Road and click run

Demolition of the original building 1993

|