|

||||||||||||||||||||||||||||

| Survey of 23 York Road, Rushden, Northamptonshire, by James Looker, Buildings Archaeologist, 2005 |

||||||||||||||||||||||||||||

|

Architectural Survey

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Abstract

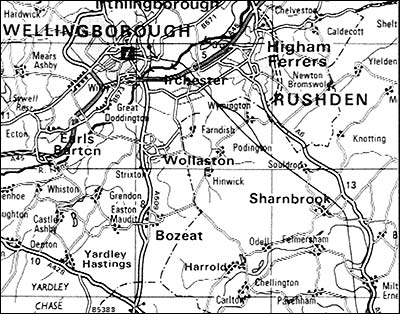

Planning and Listed building consent has been granted for the conversion 23 York Road, Rushden, which was a former boot and shoe factory, into luxury flats. A building recording and analysis had been requested prior to any works being completed. The building constructed c1890 retains many of the original features externally. At the time of the survey it was found that some documentary evidence was available, however much of the physical evidence was dependent on the main fabric of the building. Introduction The town of Rushden is situated six miles to the south and east of Wellingborough, East Northamptonshire. Much of the town’s manufacturing base was centred upon the boot and shoe industry until the collapse in the later part of the 20th century. As a result many of the former factories related to this industry have been or are becoming redundant and are being made available for redevelopment.

The proposed redevelopment of 23 York Road, Rushden (SP9612 6646), is a result of the factory becoming redundant and a successful planning application being made for the building to be converted into luxury apartments. The Northamptonshire County Council’s Historic Environment team issued a brief for the recording and analysis of the building. The brief required a record be made of the building prior to any redevelopment. This report contains a full written record with supporting illustrations and selected photographs. The survey of the building was undertaken according to the brief issued in October 2005. The archaeological brief set out the following objectives, which have all been addressed: 1. To provide a full written, drawn and photographic record of the former boot and shoe factory. 2. To enhance and substantiate the rapid survey record produced by the English Heritage Recording team. 3. To place the building within the context of the boot and shoe industry within the county and Extensive Urban Survey of Rushden. A record has been achieved and an archive created to RCHME III, this is proportionate to the level of intervention that took place. The archive remains in the author’s possession. Historical Evaluation At the time of the desktop survey very few primary documents were found and as a result maps and other secondary sources, for example trade directories were utilised.

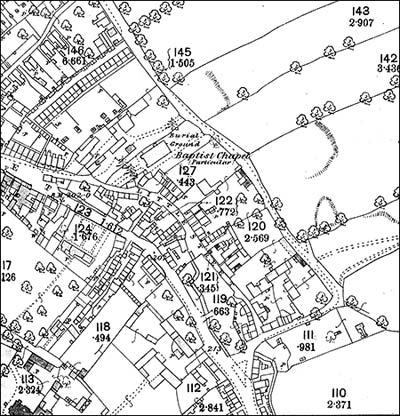

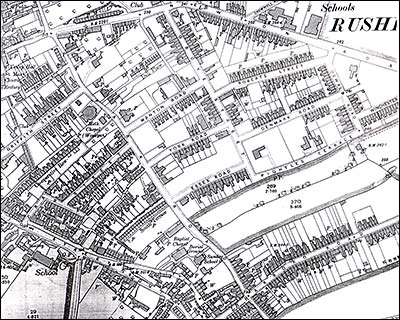

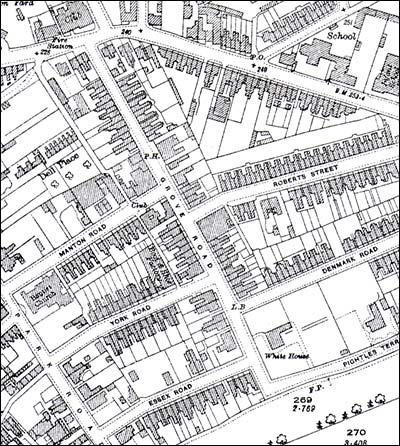

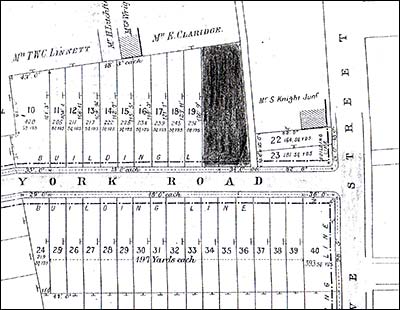

The Ordnance Survey map of 1885, (Map No: 2), indicates that the area now know as York Road had not been developed. Building on the success of the town, the 1900 Ordnance Survey map shows the development of domestic properties and industrial units expanding eastward.

The 1900 O/S map indicates that 23 York Road was a rectangular shaped building, the sanitary block well defined on the west elevation. It is suggested that the original builders and owners of the building were Knight and Bradford.

An examination of the 1926 O/S map indicates that the main building had been much extended to the rear and the central areas in filled, the layout of the factory is as seen to day. From the Kelly’s trade directory, 1903, it has been found that the owner of the building was Ebenezer Wrighton. A sales indenture dated November 1896, (Marriott collection), has shown that Wrighton purchased the building in from Fred Knight and Charles Luther Bradford for the sum of £100 – 1s – 00d.

From the 1896 indenture plan, (map no. 5), it is has been found that the frontage was 50 feet and the factory had a ground floor space of 680 square yards. Throughout the 20th century the building has had a series of owners, 1906 ownership had passed to Ellard & Howes, also boot and shoe manufacturers. A review of the trade directory indicated that in 1922 Joseph Knight was manufacturing boots and shoes from Park Road. By 1937, the ownership again had changed hands; W. S. Gilbert and Sons were now operating out of the building. In has not been established at this time the ownership during the middle of the 20th century, by the mid 1980s, the boot and shoe industry in Rushden was in decline and by the 1990s had collapsed due to the cheaper imports from the far east. In 1999 a company known as Wearproof operated from the building, sub letting part of the building space to R. E. Tully Cutting and Blocking, Tully supplied materials for the shoe and allied trades. Using redundant mail lying on the upper floors of the building it has been found that other smaller businesses also operated out of these premises. Two businesses that have been identified are High Street Designs, and Eze E Ail (?); to date no further information has been found about these companies. The Building Recording and Analysis 23 York Road, a former shoe factory, SP9612 6646, is situated on the north side of the York Road and occupies a deep plot. The building is a rectilinear shape that has seen four major structural modifications. Originally the building was two stories in height and two-thirds the size of what has been established to date. The next phase of building saw the south elevation extended westwards and the creation of a covered thoroughfare to the rear of the building. It is suggested that it was at this stage or not long after that the third storey was added. The building was to undergo further modifications initially to the rear and lastly the in filling if the goods yard. The rear addition was a single two storey range, that travelled west enclosing the yard. The yard saw a single brick wall being built with the addition of a flat roof, this lead to the establishment of a small boiler room and an enclosed storeroom. The Factory (External) 23 York Road, Rushden is on a north south alignment and is a typical late Victorian boot and shoe factory design built with orange and red brick, plate No 1. Originally the front and rear elevation was a gabled end that offered four bays with two small protruding piers that would have protected the ends of the elevation, however the frontage was extended westward creating a further two bays. An iron-railing fence with standards and gates determines the front boundary of the building. It is been suggested that these railings are contemporary (English Heritage – 2000), however a consideration must be given to that they are of a later date, possibly a 1950s copy. Railings such as these were often taken during World War two for re cycling, assisting the war effort. The rear was extended later in its history with a double two-storey north light range. click here for the floor plans The ground floor consists of six bays; bay one is a green painted panelled doubled door that allows access to the stairwell allowing admittance to the upper floors. Each door holds a single light, which has been divided into four by means of the introduction of a single vertical/horizontal astragal, (Brunskill – 1966). Contained within the frames are frosted panes of glass that restricts the view into and out of the building. The door furniture consists of a metal letterbox that has been painted over with green paint. The entrance is secured by means of a pad lock; it is believed that the pad lock is a recent introduction, introduced when the building became abandoned. Over the doorway there is a segmented arch with a single elongated keystone, this is similar to the design observed over the archway.

Situated between the doorway and the arch is a company signboard with associated logo, four lines of text, painted red on a white ground is the name R. E. Tulley, Cutting & Blocking, for the shoe and allied trades, the last line was the local telephone number Bay two is a segmental archway that incorporates an elongated keystone and stone voussoirs alternating with the brick. This archway would have allowed access to the back of the building prior to the later additions at the rear. Bays three to six, on all three floors, are single narrow windows with shallow opening lights located in the top section. The white coloured Upvc frames are a recent addition and contain toughened frosted safety glass. The design above the windows consists of a segmented arch and a drip stone/hood moulds and stringcourse that follows the contours of each of the arches. The windowsills are of sand stone and appear to be contemporary with the building. The first bays situated at the western end of the elevation located on the first and second floor levels are modern windows as described above, however the two windows at the first floor level are misaligned with all the other bays on this elevation. One reason for this uneven line maybe to allow natural light into the ‘newly’ constructed stairwell, alternatively it may be suggested that the cause for this misalignment was the introduction of a large tripartite window over the arch. This window contains a pulvinated frieze and a central light that projects from under a triangular pediment. It is suggested that this particular window has a much earlier date, possibly early Victorian, and has come from another building being introduced when the later western section of the south elevation was extended.

The top of the west-end extension has been finished off with moulded limestone scrolls; one situated to the east the other at the west, plate No 2.

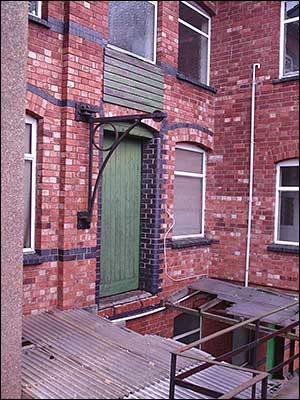

The east elevation has a much more simpler design than that of the front, south elevation. Originally the east elevation design indicated six bays, however with the later extension it now has an eight bay design. The light red terracotta bricks have been laid in a Dearne’s bond style. The style was developed c1830 by Dearne an architect; this design gave economical height with a continuous cavity c75mm, (Lynch – 1994). The ground floor originally had twelve windows, two windows per bay. The exception is the last bay; here the final window was removed with the introduction of the later extension. Each window has a white painted metal frame with a small shallow light that opens outward. At the time of the survey it was noted that the first three windows had been damaged through vandalism and as a consequence these windows were boarded up. Windows four to eight contain frosted glass panes with a diamond shaped mesh; this mesh acts as a security measure and window protection. If the window becomes damaged many of the larger the glass fragments are retained within the mesh. Windows nine to eleven are of the same design but have clear glass panes and retain the meshing. The decoration over the windows is a low-segmented arch constructed by the introduction of two courses of header bricks. The builders have not continued the design of the dripstone/mouldings as observed on the front elevation but have introduced a course of Staffordshire blue header bricks, (Lynch – 1994). The windowsills have been formed by the introduction of fifteen blue plinth headers; a course of blue stretcher bricks connects the sill line. The second and third storey windows are of the same design as seen on the ground floor, however all the upper windows have frosted glass but do not have the meshing. As a consequence, at the time of the survey many of the windows had suffered from the effects of vandalism. Bay seven is a wooden panelled blue painted sliding taking door. The door is considered modern and it is suggested that this door and associated runners date to the late 1980s, and is discussed below. Bay eight is a set of blue painted panelled doors that acted as one of the fire escapes, discussed below. The north elevation is the rear of the building and is the end of the later extension, access to this section of the building was restricted by the fact that it back onto private property; from the limited viewpoint no features were readily visible and is considered plain. It was possible to view the first and second floors of the original north elevation, four bays were present on each of the levels, and all bays were windows of a similar design to the east elevation, mentioned above. The west elevation has had the most change, originally each of the floors had the same amount of bays with the same design of windows as observed on the east elevation, some of the windows were still in situ at the time of the investigation. Entrance into the ground floor office area is accessed via the service door located at bay one. There was no evidence to suggest a stairwell at this location that would have allowed access to the upper floors. Bays two; three and five are windows similar in design to those observed on the east elevation. Bay four is a green painted wooden panelled door that leads directly into the work area, this door may also have been utilised as a minor taking in door. Above this door and secured to a green painted lintel is a wooden roller that may have assisted in the transportation of goods up to or down from the upper floors. On the first floor level bays one and three are windows, bay two is a single taking door. The door is a green painted panelled design and allows goods/materials to be taken in or out. Above this door, seven green painted wooden planks have been secured to the fabric. It is possible that the bay above was originally a taking door but was later in filled to become a further window. To the south and above the green painted door is a cast iron hoist; this has been mounted directly onto the fabric of the building, plate No 3. A visual inspection of the hoist noted that the pulley was still in situ, however a manufacturer’s mark was not found at this time.

Bay nine is a green painted metal fire exit door that leads onto a flat roof and onto a metal a fire escape stairway. A visual inspection of the stairway did not identify a manufacturer’s mark. Bays ten, eleven and twelve have been brick in filled and then hidden from view by the building of a gabled concrete tiled roof that is associated with the later extension to the rear of the factory. The most notable change to the west elevation was the extension to the south elevation, mentioned above. However, on all three floors, bays seven and eight, if incorporated into the design, were hidden from view with the construction of the sanitary block, the alleged openings were adapted to internal doors, discussed below. The sanitary block, west elevation, has two lights per floor; these small windows contain frosted glass allowing privacy to the occupants in the block. The windows located at bay six were lost when the lift tower was constructed; the window openings were again adapted to accommodate the lift doors. Bays nine to twelve, located at the ground floor level were lost when that part of the building was demolished to accommodate the later rear extension. Located at the second level bays one, two and three are all windows, however, as mentioned above bay two had originally been constructed as a taking door and later modified to incorporate a window. Bay nine, as the bay directly below was a green painted metal fire escape door, this lead directly onto a metal fire escape stairway. A visual examination was undertaken of the cast iron girders with the result that no manufacturing marks could be found. The remaining three bays are windows and are similar in design as previously mentioned. Access to the back of the original building was blocked off by the later addition to the rear; the south facing elevation of this extension holds a wooden taking in door. A series of c2.5 metre high walls were later constructed c2 metres away from the original boundary, all set on a north south alignment the ends of this construction are butted to existing structures. To the north the later rear addition, to the south to the back of the early westward extension. A flat roof was added later, thus creating extra storage space. The largest of the storage spaces is accessed internally from the rear workshop; two other smaller storage spaces are accessed directly from the service yard. Of these two spaces the larger was later adapted into a boiler room, the boiler still in situ at the time of the survey, plate No 4.

A visual examination of the boiler failed to identify a manufacturer or their trademark, the only label viewed was an orange warning sticker located top right of the machine. The internal south elevation of this space revealed a brick in filled window; originally this window would have allowed additional natural light into the stairwell. A small internal brick flue stack was added to the southwestern corner of the boiler room, this flue would have allowed harmful omissions from the boiler escape out the top of the roof. The Factory (Internal) This building has seen many internal changes and as a result many of the early features have been remove. It has been assumed that this building is a typical boot and shoe factory, so it is therefore possible to gain an understanding to the form and function to each of the floors. The ground floor area would have originally been utilised for possibly, the clicking processes, and leather acceptance, this would have been known as the “bottom stock”. From here the leather for processing would be transported to the upper levels, and the finished goods prepared for final despatch. The ground floor is accessed by a set of green doors in the earlier west elevation, originally the whole floor was open however, a series of connected office spaces has been created by the introduction of two stud walls constructed around a basic timber carcass frame, plate No 5. The lower sections of the walls are boarded whilst the top halves contain clear glass panels. The smaller stud wall is situated on the south elevation between windows one and two of the earlier building. This wall travels north approximately 3 metres. Situated in the northwest corner of this wall is a single glass panel that would have allowed the occupants of the office view any potential visitors. To the south of this panel is a single door, the upper section being clear glass, in keeping with the whole design. The return stud wall travels east and is secured to the internal east elevation, these panels contain four glass panes and a sectional glass panelled door, the door is similar in design as previously mentioned. The interior of this office space has been sub divided by the introduction of a secondary stud partition; as a consequence approximately one third of the floor space has been sectioned off creating a smaller space, possibly accommodating a floor manager. Either a small support staff for administration purposes or alternatively the floor supervisors may have occupied the larger space.

The flooring has a concrete screed covering, with the consequence that imprints of former machinery positions are clearly still visible; this is particularly evident at the northern end of the factory, the later addition. Located at bay four on the interior west elevation is the taking in door, mentioned above. Bay six, houses a single lift door that possibly dates to the early 1970’s, plate No 6. The lift has a stainless steel finish with the door opening internally, from the design it is suggested that this lift was not intended to transport people. It is suggested that, this was a dedicated goods lift, which would have enabled goods and materials to be transport up to or down from the upper levels. On closer examination no evidence could be found of the earlier window structure, however it was noted that this lift replaced an earlier lift that possibly date to the mid 1930’s. A small brown plate, possibly painted cast iron was located to the left hand side of the lift doors. This cover was a control/calling panel that engaged the earlier lift, no information has been found to date relating to this lift. The later lift was under Thorpe contracts, no information relating to this company has been found to date. Internal bays seven and eight are internal doors into the sanitary area, both areas contained a single white porcelain toilet and white washbasin with associated pedestal. With no evidence of urinal it could be suggested that the W/c’s were for female usage, however it could be argued that with no distinct identification, either the W/c’s were duel purpose or alternatively the employees knew a known demarcation.

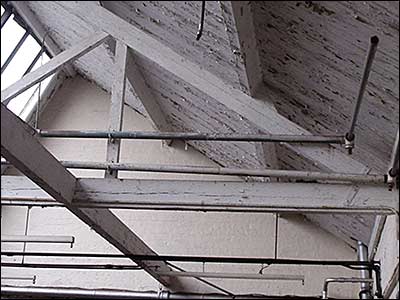

Although not visible from the outside structure there is evidence to suggest that the original building had been extended to north twice. It is suggested that the original gabled end was situated after bay five, tenth window. A single green painted cast iron column supports three white painted cast iron “I” RSJs, these beams are all boxed in and are secured together; they travel eastward and are tied into the fabric of the east elevation. Three additional white painted RSJs travel from this single column south; these are also tied into the main fabric of the building. A visual inspection of the RSJs revealed a manufacturer’s embossing mark, “GLENGARNOCK STEEL”. No further information has been found to date about the steel company Glengarnock. Evidence of the later gabled end appears approximately 3 metres north from the single column. Two cast iron supports, plate No 7, have been strategically placed; the first was in a direct line with the single column, and the second approximately 3.5 metres to the east. The pillars were green/white or blue painted cast iron and supported three white painted RSJs. These RSJs travelled in an east west direction, the first set of RSJs were supported at one end by a brick pier located in the east interior wall the other end was supported by a column. The second set of RSJs was supported at either end by the columns. The RSJs carried the same embossing marks as mentioned above. A closer visual inspection of the brick pier would suggest that the design was not an integral part of the building but a later addition. Secured to the brick pier and travelling west toward the cast iron column, a stud wall had been constructed around a basic timber carcass. This stud wall may have acted as a safety barrier to stop factory traffic travelling south down the east side, alternatively it may have been utilized as a dedicated work area. As mentioned above, the rear of the building was a later addition, the south interior wall holds two bays one, a set of taking in doors and an internal door that leads into a storage room. At the time of the survey this room contained basic timber racking constructed around a wooden carcass frame. The north interior elevation had three bays, which consisted of brick constructed blank arches, the west interior elevation had five bays, and these were also brick constructed blank arches. Located in the northwest corner of this part of the building, an extractor fan has been secured to the wall fabric. The vented gases are exited through this wall. A number of silver coloured pipes travel into and out of this system. A visual inspection of this extractor fan noted that secured to the bottom left hand corner is a logo/manufacturer’s label, “ITT REZNOR”. No information about this company has been found to date. The east elevation had two bays both bays were doors. The first bay located to the north is a blue painted panelled fire exit door that leads directly into an alleyway. Located next to this door way are the electrical fuse boxes, which have been painted, five are red, and the sixth green over red. There are also four grey metal fuse boxes associated to this system The second bay to the south is a sliding blue painted panelled taking in door. From the height of the threshold of the sliding door to the ground floor working surface it is suggested that for goods being delivered/despatched a primitive ramp would have been required, alternatively the goods may have been man handled in/out, later a fork lift truck utilised.

Located in the floor fabric, as mentioned above, there are the footprints of earlier machinery. It has not been possible to assign a machine to a particular impression. Situated close to some of these indentations it was noted that there were faint traces of yellow paint, closer inspection found that this paint formed chevrons. It is suggested that these chevrons were marked out to indicate either safe areas for pedestrians to walk/work, alternatively defined areas for transporting goods around the factory. The workspace was open and it was possible to view the roof construction. The roof construction is a double gable design that commences over the above-mentioned RSJs. Two roof trusses are secured at one end to the beams and travel north, they are rested on another set of RSJs that are supported by a further two cast iron columns approximately c3.5 metres away. These two piers are directly in line with the other supports. The trusses support two equally spaced through purlins secured to either side of the roof trusses, plate 8. To the south, the roof trusses support untreated timber planks, these in turn carry red coloured concrete tiles.

The north side of the trusses support skylights, all lights hold approximately 1 x 1.75 metres frosted panes of glass. The second gable commences on the RSJs, the trusses travel north and are secured into the main fabric of the building, this gable is constructed in a similar way to the first, mentioned above. Access to the first and second floors is via the green painted door located at bay one on the front elevation, mentioned above. The route up to the first floor is via a series of doglegged concrete steps, these steps also continue up to the second level. Access is gained onto the first floor via a green painted modern door. At the time of the survey a heavy grey metal padlock secured the door. It should also be noted that at the time of the survey some of the machinery associated to this building had been abandoned and was situated on the first and second levels. Originally, the first floor level would have seen the operations of “welting” and “finishing”, it is suggested that these operations may have continued up to the time the building became redundant. The front of this floor had been given over to office space. This space had been created by the introduction of two white painted wooden stud walls that travel parallel from the door opening to the west finishing and being attached to the fabric of interior east wall at the start of bay three. The northern partition had a single internal door that opened north and accessed the working floor area. The second south partition wall, approximately 1.5 metres from the northern partition had three internal doors, all three opened south and accessed the offices. These office spaces were created by the introduction of two internal stud partition walls. It is suggested that the first office space, c3x2 metres, which is accessed by two of the doors may have been an administrative area, possibly supporting a small typing pool and possibly book keeping personnel. The middle office, c1.5x2 metres, the smallest of the three spaces and accessed by the third door may have been occupied by the manager/owner of the company. A fourth internal access located to the east of the third door is situated on a north/south alignment accesses the third space, c3x3 metres. At the time of the survey a number of display shelves were still in situ. These shelves were possibly designed to present publicity material, such as books and pamphlets, and it is therefore suggested that the marketing department may have occupied this area. At the time of the survey the floors were covered with modern carpets and as a result obscured the floor construction. Access to the work area is as described above, at the time of the survey the floor was open, and it was possible to see the floor construction. The floor construction design was close-boarded with boards fixed across the joists, (Brown – 1982). This type of design allowed boards of varying widths to be used, however the boards located on this floor were of a uniform width and thickness. It is also suggested that this type of design is found in the office area, mentioned above. The layouts of the window bays internally are as described above, however it is possible to view the brick in filling of bays ten, eleven and twelve on the internal west wall, these bays were brick in filled when the later ground floor extension was constructed. Situated adjacent to the first floor lift doors are two trap doors that had been made secure. It is suggested that these trap doors preceded the both lifts, mentioned above, in transporting goods and materials up to or down from other floors. The lift entrance at this level is a blue painted metal door. The sanitary area and wares are the same as observed on the ground floor and are mentioned above. Located on this floor, near to the bay three-east elevation and adjacent to the stud walling, an air compressor had been abandoned. Due to its position it was not possible at the time to view this apparatus thoroughly and therefore establish a manufacturer. The concrete stairs mentioned above gives access to the second floor level; originally the second floor would have seen the processes of “closing” and “closing preparation”, it is suggested that these operations may have continued up to the time the building became redundant. As seen on the first floor, the front, south of the building had been given over to office space; the construction and design of these office areas are mentioned above. However, in the office space accessed by the two internal doors additional floor surface has been achieved by the building of a raised stage/ platform c2x2 metre area over the stairwell. The construction technique consisted of wooden floorboards attached to flooring joists; these joists were embedded into the main brick fabric of the stairwell and west interior elevation. The construction of the raised area obscured the top of the window located to the west of the south elevation, only a partial arc of the brick segmented arch was visible. Access up to the stage area was via a wooden clear-varnished two-tread stair. Located on top of this platform was a black cast iron fretwork frame from a “Singer” sewing machine. The function of this area is not known at this time, although it is possible to surmise that the area may have been used for temporary storage. At the time of the survey, these office spaces contained basic timber framed racking constructed around a timber-framed carcass. It suggested that these areas once offices were subsequently adapted for temporary storage. The floor construction is of c75mm thick wooden panel boards; these boards were attached to the flooring joists. Owing to the nature of the construction of this flooring it is suggested that no heavy machinery was located at this level, although smaller industrial boot and sewing machines may have. As mentioned above, there was evidence of abandoned equipment still in situ at the time of the survey, see appendix 1.

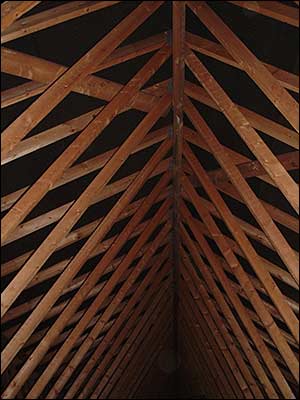

The lift, sanitary areas with associated wares are as mentioned above. As observed on the first floor, the space that the trap doors occupied and that predated the lift(s) had been made secure with the consequence that no further information was made available to make a reasonable analysis into its operation. All other internal features had been removed prior to the abandonment of the building. An examination of the roof space, plate No 9, revealed that the roof trusses, purlins and common rafters have been replaced in the recent past, c late 20th century; as a result there is no information into the roof’s original construction. Conclusion 23 York Road, Rushden is part of the Boot and Shoe heritage of Northamptonshire. Throughout the building’s history it has to date been utilised within that industry. With the decline of this regional commerce, like many other Boot and Shoe factories of the day, the building has become redundant and as a consequence ideal for development. On this occasion the developer, Mr Marriott, has opted to keep this building and adapt its former function into apartments. The building as a whole has a typical design for this type of industry and there are other similar examples within the county. Bibliography Anon 1903, 1906, 1910, 9141, 1920, 1924, 1928, 1931, 1936, 1954, 1956, 1960, 1964, 1966, 1970 Kelly’s Trade Directory - Northamptonshire Anon 1958/59, 1960/61, 1963, 1966 & 1969 The Leather Trade Year Books Brunskill R.W. 1966 Transactions of the Ancient Monument Society, Vol. 13 A Systematic Procedure for the Recording English Vernacular Architecture Brown R. J. 1982 English Farmhouses, (P282) English Heritage 2000 Northamptonshire Boot and Shoe Industry, Rapid survey Record Foard G. et al 1999 Northamptonshire Extensive Urban Survey Lynch G. 1994 Brickwork, (History, Technology and Practice), Vol.1 (P238) O/S Map Rushden 1885 Northants Lby 40/10 O/S Map Rushden 1900 Northants Lby 40/10 O/S Map Rushden 1926 Northants Lby 40/10 Appendix 1 - click here Floor plans and Machinery found inside. The illustrations and photographs contained within this report may not be reproduced without prior permission of the author Acknowledgement For a photo album of the factory click here Ebooks and scroll down for 23 York Road and click run |

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

By kind permission of Mr. James Looker

|

||||||||||||||||||||||||||||