The Rushden Echo and Argus, 21st August 1959, transcribed by Jim Hollis

Closing room changes will speed up work

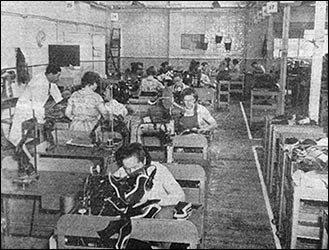

Monday morning brought excitement, if not actual surprise, for women and girls employed by Sanders and Sanders, Ltd, the Rushden shoe firm. They returned from holiday to find their closing room fully modernised on the principle that comfort and efficiency run hand in hand.

The changes, though chiefly concerned with the placing of machines and the system by which the work is routed through the department, have in addition an appeal to the eye. They are typical of the efforts made by the industry to smooth-out production snags and at the same time make factory life more attractive to the workers.

|

|

|

Some racks arrive near the machine of

Miss Marion Brown, who selects one, with

the approval of Mrs Millard, forewoman.

|

The works manager, Mr D Denton, keeps an eye on

the working-out of the new system as girl closers

get used to the individual benches.

|

Boot-making by the Sanders family in Rushden goes back to 1873, when William and Thomas Sanders began the business at the corner of High Street and Station Road. Mr. Tom Sanders and Mr. Leslie Sanders, both sons of William, are the present directors, with Mr. Gerald Sanders, a son of the senior director, playing an active part as representative of the third generation.

In the whole story of change and progress through 86 years, a fire in 1924 stands out. It ruined the firm’s factory in Spencer Road. The premises were rebuilt and have since been enlarged, the additions including – in the 1930’s – the section which became this closing room.

Prior to the recent holiday the “girls” sat at long benches in facing rows of up to eight, and as many as 16 machines would depend on one motor.

Easier Now

In the new set-up the machines have been remounted on 68 individual benches, each with its own one-third h.p. motor. There is no clutter of shafting underneath, and no rummaging in skips for the work. Placed in line-ahead form, the single benches make each operative readily accessible, and the work can now travel smoothly on a new outfit of seventy light-running racks.

There are three shelves to a rack, each holding two dozen uppers – still the normal work-ticket quantity. The “outsides” and the linings intended for them will travel together from the start, and in one way and another, a minimum of fetching, carrying and sorting-out is the aim.

Planning of the flow is indeed the key-point of the new system; the sequence of operations – depending, of course, on the style of the footwear – is decided by the forewoman and recorded on the back of the work-ticket. The ticket pops into a slot at the end of the rack, and the rack has its own conspicuous number.

Overhead in the department are numbers showing the location of the various operations, so it should be easy both to locate a particular lot of work and to keep it moving according to the sequence. Work, moreover, should always be a hand as required by the girls.

Days Saved

Reduced to simple terms, the new planning means that work should go through the department in four days instead of the previous average of seven.

The effect of colour has been considered; it is thought that the deep lilac of the benches and the café-au-lait of the racks will be congenial and that congenial colour helps towards comfort and efficiency. Lighting has under gone complete rearrangement, with needle light supplementing the main flood of fluorescence. The whole room has been re-decorated.

Elimination of noise has been another aim. The small motors run very quietly, and the racks move willingly in any direction.

The general installation has been supplied by the British United Shoe Machinery Co., to their own plan, but incorporates some of the shoe firm’s own ideas.

Although Sanders and Sanders share a factory at Maltby, Yorkshire, and have a large proportion of their closing done there, they are still up against the female labour problem, and the present speed-up is important to them, especially in connection with punctual delivery – a factor much to the fore in overseas trading.

|