| Extract from a 1983 catalogue

What makes A Grenson Shoe A Grenson shoe?

Since William Green founded Grenson in 1866, the shoe industry has changed dramatically.

Today, most shoes are mechanically mass-produced instead of lovingly hand-crafted in the old time-honoured ways.

|

Clicker, with his knife and strop

|

However, at Grenson shoes are still made to a standard set by tradition and not by the dictates of modern mass-market requirements.

Since 1866 Grenson has been combing the world for the finest leathers and skins:- Chinese kid from the foothills of the Himalayas; nappa from the Greek Islands; the best calf from France; antelope from Africa and lizard from Indonesia.

Grenson clickers, each of whom has served a long apprenticeship before winning their place at the bench, use hand-made knives of their own design to cut the precious raw materials, avoiding tiny imperfections in the grain which could blemish a toe cap or spoil an apron.

|

|

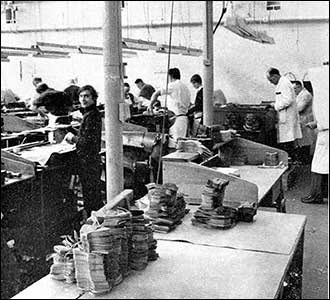

Clicking department in 1966

|

|

The stitched uppers then spend a minimum of 24 hours in the humidifying room, becoming even more flexible and workable.

While still in this damp, mellow condition they are hand tacked to lasts which could be made from Canadian rock maple or beech.

Over the next five days, they will gradually dry out on the last, conforming to its gentle contours so that the shape created there will last for life.

At every stage in the eight weeks it takes to make a Grenson shoe, the attention to detail and sheer pride of craftsmanship amazes the outsider.

As many as four different waxes are used to polish oak tanned sole leather; cotton for laces comes from as far as Egypt and Ireland supplies the best rot-proofed linen thread for sole stitching.

All this knowledge and skill wasn't arrived at overnight. It is the product of almost 120 years accumulated management and technical experience, both in the Board Room and on the Shop Floor where father and son in a unique partnership have handed down their knowledge to their successors; each generation building on that experience and incorporating the best of the new with the lessons of the old.

That's why a Grenson shoe is so unmistakably a Grenson shoe.

|