|

|

||||||

| The Evening Telegraph, 20th June 1973, transcribed by Jim Hollis |

||||||

|

25 Years of Growth for Cox & Wright

|

||||||

|

||||||

| Cox and Wright Ltd. the Rushden engineering firm this year celebrate their 25th anniversary – 25 years which have seen a remarkable growth in a firm which specialises in making footwear manufacturing machinery, but which has now also diversified its interests into other fields. Its annual turnover is over £1 million. In the last 15 years there has been a revolution in shoe manufacturing methods – a revolution in which Cox and Wright have played a major part by producing equipment which has helped streamline footwear production. In the last few years, outside of footwear machinery, Cox and Wright also have been making machinery for a variety of industries – from car components to the corset industry. And in each aspect of the business there are world-wide sales for the Rushden made plant.

The formation of the company really goes back to 1945 when the two companies which now make up Cox and Wright were formed. On November 17, 1945, the company of Cox and Son (Rushden) Ltd. was set up under the chairmanship of Mr. E. Cox. At about the same time Mr. George Wright left the British United Shoe Machinery Co. to start his own company under the name of George Wright Shoe Machinery Services. Two year later Mr. Cox and Mr. Wright decided that in order to make better use of their individual facilities and to exploit the market potential, a merger of their interests would be a sensible move. The two companies were amalgamated to form a single operating company under the name Cox and Wright (Shoe Machinery) Services Ltd. Working from small premises at East Grove, Rushden, with only 13 employees (now there are over 170), the new company began producing custom built work benches for the shoe industry, and operating a machinery repair and renovation service. It was recognised that eventually this business would reach saturation point and there was a need to diversify. And already the company had proved their inventiveness by making and fitting special extractors to work benches and marketing them as a unit. These were selling in large numbers.

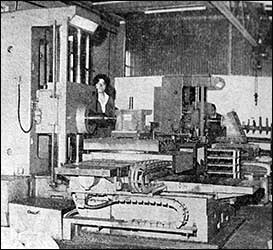

Overtures were made to the firm of SAGEM in France, who were manufacturers of a range of mechanical swing beam clicking presses. They were successful and Cox and Wright were appointed United Kingdom agents for the sale of all SAGEM shoe machinery. This gave the company the opportunity it was seeking and proved so successful that another agency was sought, this time for a range of vulcanising machines to cater for the growth in the use of vulcanised rubber sole and heel units. The business continued to expand and it became obvious that the existing premises were too small to cope with all the expansion. Plans were put in hand to look for a new site and, in 1959, Cox and Wright moved to the site in Wellingborough Road, Rushden, which they occupy today. In 1963 the company diversified into pneumatics by taking on the agency of Benton and Stone. This enabled them to not only sell equipment to the trade but also to obtain equipment for their own machines. With an eye to increasing manufacturing potential, in November 1965 Cox and Wright acquired the assets of another Rushden company, Fred Hawkes (NV Engineers) Ltd. Following a period of successful joint co-operation, an agreement was reached on May 11, 1967, which allowed Evode Holdings Ltd. of Stafford (the parent company of Vik Supplies Ltd) to acquire all the issued share capital of Cox and Wright and its subsidiary companies. For some time the company’s product development department had been interested in high frequency welding and embossing techniques with PVC materials, and in 1968 it was decided to concentrate in this field of activity. The footwear industry had for some years been interested in the development of PVC materials for footwear, and Cox and Wright were quick to realise the potential in this area and to develop high frequency techniques for it. Today, the shoe industry uses vast quantities of these synthetic materials and Cox and Wright are acknowledged as leaders in this field. Cox and Wright are now working for a wide range of industries, although eighty per cent of production is still for shoe machinery. But machinery has been made for allied industries like the handbag, wallets, fancy goods manufacturers and luggage manufacturers; but also many others in quite different fields. These include machinery for the manufactures of car components, clothing, corsetry (a Cox and Wright machine makes the padding for bras), toys and sports goods. Machinery by the Rushden Firm for manufacturers in all these fields is now exported worldwide. They have customers in all five continents – including many eastern European countries. China and various African countries. |

||||||