|

||||||||||||||||||

| Gordon Cox, 2007 |

||||||||||||||||||

|

Cox & Wright

|

||||||||||||||||||

|

||||||||||||||||||

|

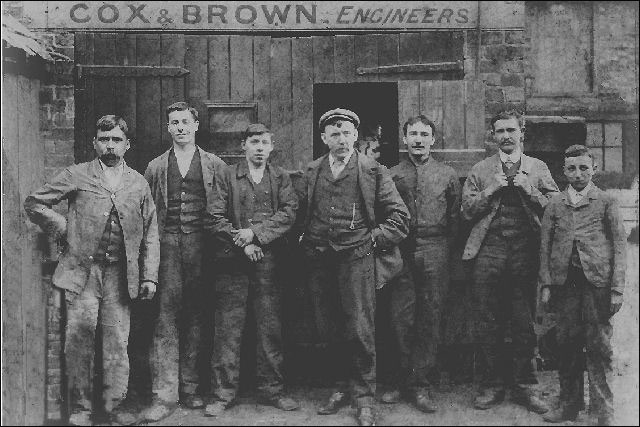

Albert Cox served his Engineering Apprenticeship at Woolwich Arsenal and moved from Erith in Kent to Rushden in 1893 to take up the job of Chief Engineer at the factory of John Cave and Sons. In 1899 just before Cave's disastrous fire of 1901 he decided to go into partnership with an electrician, Fred Brown.

In those early days they could install telephones, their own Telephone number being 1Y. They also serviced the large oil engines which most of the factories powered their machinery with in the Rushden area. This led to a demand for Belting, Pulleys and all the other ancillary products that were needed to keep the wheels turning. |

||||||||||||||||||

Albert also designed and built shoe machinery, and was granted several patents. One of his most successful was the Cox and Brown Slugging Machine. From a coil of wire, rectangular in section, it would shear off 'slugs' of the wire and drive them in a neat row around the heel of boots, this extended the wear life of the heel.

At sometime before the First World War the partnership was dissolved, but the business continued as Cox & Sons for many years. Later, after the war Machinery Sales became more difficult, this was partly due to the firm's main competitor. The British United Shoe Machinery Company. Their vast range of machinery was leased to the customer with the stipulation that competitors machinery could not be used in the production line alongside theirs. By the slump of 1932 the firm had collapsed, but Albert managed to keep a good supply of spares in stock which he was still sending to his customers in the early years of the Second World War. Albert died in 1943. Edgar Cox, one of Albert's sons left to start up his own general engineering business E Cox (Engineers). This was situated over Mr Chettle's horse stables in Fitzwilliam Street. In 1938 he was joined by his son who had left school in that year. By this time a larger workshop had been acquired at No. 65 Moor Road. During those early years of the war there was an acute shortage of new machinery, and spare parts were difficult to obtain. The firm specialised mainly in repair work for the Boot and Shoe Industry. Machinery was predominantly belt-driven so there were always plenty of pulleys to be re-bushed and worn shafts to be replaced. If a broken part was unavailable the old part would be welded and refurbished. |

||||||||||||||||||

|

The association with George Wright began during the war years while he was working for the British United Shoe Company. He would often bring in repair work from factories around the area thus establishing what eventually would become a permanent connection between the two surnames. During the war the firm also contributed to the war effort by manufacturing small aircraft parts. Moulds for incendiary bomb moulds were also made for Alumasc Ltd of Burton Latimer. Also manufactured were large quantities of brass screwing wire, this material was used in the manufacture of munitions footwear. The use of other metals being prohibited, because of the danger from sparks, which could trigger an explosion. Production ceased shortly before the end of the war. Another move was made to shared premises in Higham Ferrers, but 1944 they had moved yet again to East Grove in Rushden where they remained for several years.

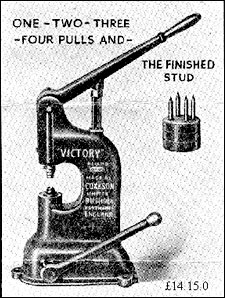

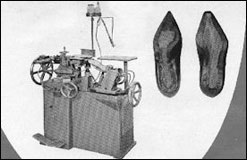

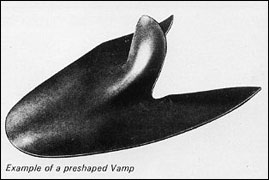

Skiver was used to feather the edge of the new half sole so that it blended smoothly into the remaining part of the old sole to create a neat finish. For companies producing Half Soles in quantities a larger, motorised version was available at £18.18.0. The last known request for a spare part was 1977. In 1945 the company, now well established changed its name to Cox & Son (Rushden) Ltd. It had also become a leading manufacture of machinery for the Shoe Repairing industry, at one time producing in excess of 200 Hand Skivers a month to satisfy demand. Several other small hand operated machines were also made.

Large quantities of hand operated Stick-on-Presses were produced for repairers, for the attachment of adhesive coated soles. The lower pressure pad was leather over a rubber membrane and the container filled with Water Glass, a liquid usually used for pickling eggs.

With safety in the workplace becoming an issue three versions of Safety Devices were designed for British United clicking presses converting them from single handed operation to two.

In 1947, on July 3rd, the association that had been built up over the years between Edgar Cox and George Wright became a formal merger of Cox & Son, and George's Irthlingborough metal fabrication business. The new company was to be called Cox & Wright (Shoe Machinery Services) Ltd. The company gradually expanded the existing premises in East Grove to accommodate the space required for the new fabrication department, which was first housed in a Nissen hut, and later by adding a brick built extension. |

||||||||||||||||||

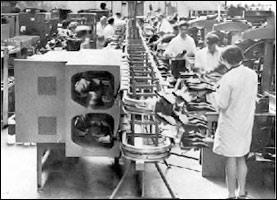

The early 1950's saw significant changes in the shoe industry, with a move to get rid of line shafting and the big oil engines. Machines became individually driven by having their own electric motor; giving more production flexibility throughout all the departments. This gave the company the opportunity to produce hundreds of Closing Room self contained individual Benches to cover a customers requirements. Sometimes, removal of the old and installation of the new would part of the deal. Closing rooms benefited by having small 2 or 3 tier metal trolleys for speeding up the movement of upper components through the department. Thousands were made, of various designs. |

||||||||||||||||||

|

||||||||||||||||||

|

In 1958-9, with the firm's growth demanding ever more space, a new factory was built on a 1.56 acre site at Sander's Lodge - 3,000 sq. ft. of office space and 9,000 sq. ft. of work area.

In 1960 the firm acquired the agency of Benton & Stone Ltd (later known as Enots), suppliers of pneumatic equipment, which was later augmented by the Norgren agency to lay the foundations of the pneumatic division. George Wright gave up his position as Managing Director in 1963 and his place taken by his son Malcom Wright. Gordon Cox became Technical Director, assuming responsibility for design and development, whilst Edgar Cox, by now retired, enjoyed a well-earned rest after a lifetime in engineering. |

||||||||||||||||||

|

Diversification was a key theme in the sixties: for instance, 1,000 vending machines were made for Autobars Ltd. in 1965. That same year the company was floated on the Stock Exchange and became a public company and Roy Peake was appointed Production Director.

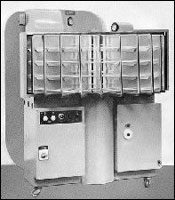

The Company's products during the late sixties were directed mainly at the Shoe Industry in which it had made it's name, Powered Making room tracks, and the Eatough-Satra Work Transporter System for Closing rooms, followed later by Rotary Moist Heat Setters and Mulling cabinets were all in constant demand. |

||||||||||||||||||

|

||||||||||||||||||

|

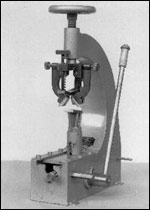

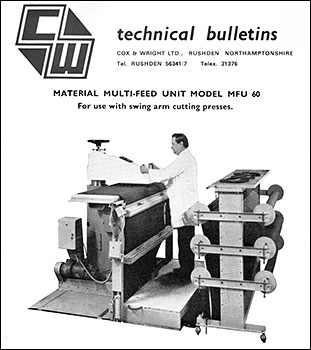

The first Travelling Head Presses were made in 1969 followed by the development of High Frequency Welding Presses. These new products enlabled Cox & Wright find outlets in many other industries. In 1970 the new CW120A Swing Arm Clicking Press made its debut.

|

||||||||||||||||||

The complete system was set up in the factory for Leyland to view before installation. Management and staff arrived in a fleet of cars on the morning of the demonstration and assembled around the machine. The Trade Union representatives took one look at it and said. 'We are not working that'. With that comment they got into their cars and left. The dispute was eventually settled and the machine was installed |

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||

|

||||||||||||||||||