|

Examinations were a regular feature of study at the Boot and Shoe School. Reproduced here are two exam papers for the qualifying exams taken by candidates for the 1936 elementary stage relating to uppers and bottoms, and the 1949 advanced stage in pattern cutting. If anyone can provide us with answers to any of the questions, we would be very pleased to publish them for you.

|

|

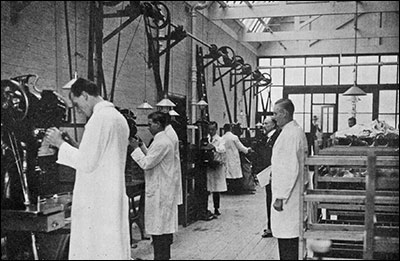

Photo of the welting, rounding and stitching department of the Boot and Shoe School, 1936-1937

|

|

Examination in the Principles of Boot and Shoe Manufacture Monday 20 April 1936

Elementary Stage

Instructions to Candidates:

3 hours are allowed for this paper – 7pm - 10 pm

The Examination Paper is divided into two Divisions – I Uppers, II Bottoms – and a General Section.

Candidates must satisfy the Examiners in one Division AND in the General Section and AND MUST SELECT THAT DIVISION IN WHICH THEY HAVE ENTERED FOR THE PRACTICAL TEST – UPPERS OR BOTTOMS

Candidates must NOT attempt more than eight questions.

The figures in brackets at the end of each question indicate the marks allowed for correct and complete answers.

Division 1. Uppers

Not more than six questions to be attempted from this division, together with two from the General Section.

- 1 Explain exactly how you would mark up a last for the cutting of a forme. For the purpose of locating the counter, joint and instep points, assume that the last is a men’s size 7. (10)

- 2 Describe a method of cutting a shoe standard pattern and give the measurements you would use for a men’s last, size 7 (15)

- 3 What allowances for closing would you make in cutting the working patterns for a Goloshed Balmoral boot which is to be made from medium substance Box Calf? (10)

- 4 Show by sketches the differences in shape between a skin and a side of upper leather, and mark the different parts of each to show their relative quality. (10)

- 5 Draw a diagram to show the lines of tightness in a Box Calf skin and the way in which shoe quarter patterns should be placed. (5)

- 6 What is meant by the tem “system” as applied to the cutting of upper leathers, and what are the conditions under which a system can be used to advantage? (10)

- 7 Explain the various methods in use for marking the sections of uppers for identification in the Closing Dept. (10)

- 8 Describe and Illustrate with sketches, the various seams and edges used in closing, and state the purposes for which they are used. (15)

- 9 Draw a diagram to illustrate the difference between a lock stitch and a chain stitch, and name the purpose for which each is used in closing. (10)

Division 2 Bottoms

Not more than six questions to be attempted from this division, together with two from the General Section

- 10 Name the different kinds of bottoming leathers in general use and state the parts which are cut from them. (10)

- 11 Describe the various kinds of presses and knives used for cutting bottoming leathers. (15)

- 12 In what way do the various preparatory operations assist the making processes and improve the footwear? (10)

- 13 Explain the order and direction in which the various strains or pulls should be taken in the operation of lasting and their effect on the results obtained. (10)

- 14 Explain what is meant by a) direct and b) indirect methods of attachment. Give two examples of each. (15)

- 15 State the methods used for the temporary attachment of soles for a) Blakesewn, b) Welted (10)

- 16 Describe the heel scouring process and state the conditions necessary for obtaining good results (10)

- 17 Draw a diagram to show the sectional view of an edge trimming cutter and name the various parts. (15)

- 18 Describe the character and uses of inks and waxes in the finishing of footwear. (10)

General Section

Not more than two questions to be attempted from this section, together with six from either Division 1 or 2

- 19 Explain the difference in character of the bones of the foot at different stages of development. (15)

- 20 The length of two lasts is 6 and 9 inches respectively: what sizes doe these represent according to a) English and b) French systems of measurement? (10)

- 21 What is the meaning and purpose of Pitch and Toe spring as applied to lasts? (10)

- 22 Explain why the last is longer than the foot. What other differences are there between the foot and the last? (10)

|

|

|

Picture of the teachers at the Boot and Shoe School 1931, including J. Korn, P.Y. Golding, R.W. Brookes and J. Blakeman

|

|

|

|

|

|

Photo in Rushden Echo & Argus 18th April 1930 - Shoemaking Exam

|

|

Exam paper Advanced 1949

Division 1 Pattern cutting

- 1 Describe and illustrate with sketches some common faults in forme cutting and their effect on the fit of the upper

- 2 In designing the outside sectional patterns for shoes how would you take into account a) economy of material and b) ease of clicking and closing

- 3 Describe how you would remedy these faults a) fabric vamp linings “bursting” at the side seams and b) leather quarter linings “bursting” at the back seam

- 4 In grading upper patterns it is necessary to vary from strict proportions in certain positions. Explain the reason for this and give three examples

General section

- 29 Explain the following terms a) lasts of different fittings, b) heel-to-ball fitting of footwear and c) sets or groups of lasts

- 30 Describe briefly the production of either a) vegetable tanned sole leather or b) chrome tanned upper leather

- 31 Write a brief account of one of the following:

- a) Grindery of various types used in the shoe industry

- b) Cotton fabrics used for shoe linings, or

- c) Uses of rubber in the shoe industry

- 32 What are the common causes of damages in the factory and how can these be reduced to a minimum? Give examples from your own department

Students took many tests in the course of their studies at the Boot and Shoe School, and three original papers are reproduced here from the 1940's:

|

|

Test paper on the marking up of a last

|

|

|

|

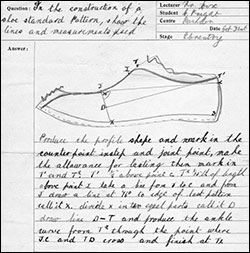

Test paper on the construction of shoe patterns

|

|

|

|

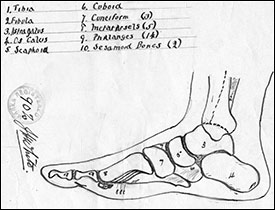

Test paper on the bones of the foot

|

|

|