|

||||

| The Rushden Echo 10th August 1923 |

||||

|

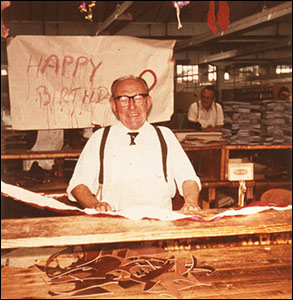

New Tecnic Factory

|

||||

|

||||

|

LARGE NEW FACTORY AT RUSHDEN The spacious new factory in Bedford-road, Rushden, just beyond Mr. J. Wilmott’s farm, and owned by the Tecnic Boot Co., Ltd., will be opened after the holiday. The principal of the firm, Mr. W. C. Tarry, very kindly showed a 'Shoe Trades Journal' representative all over the building. It stands on ground measuring 132 ft. along the frontage by 90 ft. (front to back), and is one of the most pleasantly situated factories in Rushden, magnificent trees being on two sides and open fields around. Messrs. W. Packwood and Son, the builders, have erected the factory on modern lines. Everyone in the building will work under the best possible lighting conditions, an abundance of light flooding down from the “American” shaped glass roof, the northern aspect of the roof being glazed, while the southern slopes keep out the heat of summer. About 30 big, permanently open ventilators maintain a supply of fresh air. Departments are planned on the approved principle of avoiding unnecessary carrying or wheeling backwards and forwards of boots in the making. Materials, coming in on one side, will be cut up and pass the various processes, traversing the whole factory to the dispatching department, which is easy of access from the road. The entrance for the men is on the front, and that for the women and girls at the end facing Rushden. There are dining rooms for employees who stay to dinner, provision being made for heating dinners at a large stove. Tables and chairs are being provided. The rooms are very pleasant, the men’s having two windows looking out over the fields. Drinking fountains are fitted in the various departments in the factory, handy for any employee.

An interesting feature of the equipment of the factory is the fact that the power (which is by electrically driven motors throughout, thus ensuring a maximum of smooth-running efficiency with a minimum of noise) is taken direct from the new mains from the Northampton Electric Power Station, and the factory is the first in the district to be supplied from this new source. A special transforming chamber has been constructed in a portion of the building for the purpose of transforming the high-tension current down to the lower voltage at which the motors can be driven. The electric lighting is on the latest principle, so that an even light is distributed all over the factory, and the whole of the installation of the motors and wiring and lights has been done by the Rushden Electric Supply Company, under the direction of Mr. Benson, the resident manager. The offices are on the front toward the north end, the other side of the employees’ entrance being for the dispatch department. Beneath the latter is an extensive room, partly underground and partly above. A large trapdoor divides this lower room from the dispatch department, so that if any large number of boots is completed but not immediately required for dispatching they can be lowered into the “cellar,” giving more space on the ground floor for packing, etc. A strongroom is built in near the general offices, the material with which the dividing walls of the offices is made being a patent fireproof and soundproof substance. A commercial travellers’ waiting-room, another for interviews, and office for the reception of buyers, and a private office for the principals are additional to the general offices, from which a view of the whole factory is obtained. Efficiency in output, operations made as pleasant as possible, and the health of the employees have all been studied in the erection of this well-equipped factory.

|

||||