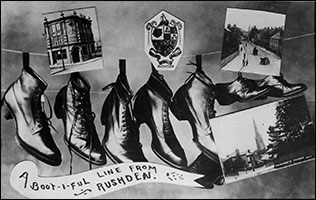

Until the 18th century shoe making was very much a local trade, with leather tanned in the villages that were near to water. Here in Rushden the early tan pits were to the south of the village near the brook. The village shoemakers would have sold their wares within the village and any surplus was taken to the markets at Higham Ferrers or Wellingborough.

|

|

|

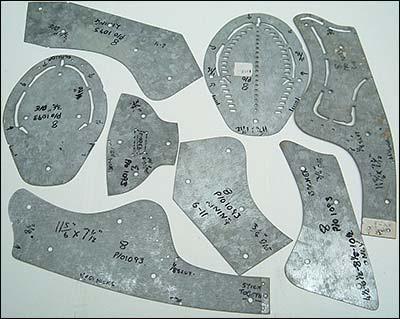

Patterns for cutting out uppers

|

|

When the Turnpike road from London to the North came through our town, the trading area widened and by the mid 19th century the whole trade was beginning to get “organised”. Men started to work in co-operation with one man cutting, another sewing, one lasting, and so on, until one would take over the organisation. He would send an “errand boy” to deliver bundles of work to the men for them to complete their part of the operation, and this would be collected as the next batch was delivered.

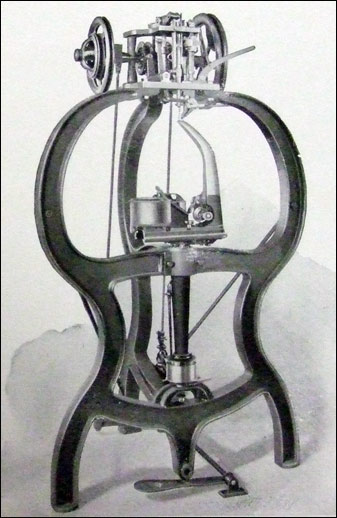

Engineers were meeting the challenge to invent machinery to do some of the work, starting with presses for cutting the leather. The sole presses came first, then the “Blake Sewer” for the heavy sole stitching. Machinery, being heavy, was static, so the men were brought into the building to work rather than working alone in their “shop” in the yard behind the house. Instead of delivering the work to their employees the entrepreneurs drew the men into their manufactory and the whole trade became more orderly.

Work was organised into cutting, stitching and finishing. More machines were invented to do the other sewing tasks, then for most of the other operations; riveting, eyeleting, trimming. The factories were growing in size and in the early 1900s trade expanded quickly with some large government contracts to supply army boots. Women began to do some of the lighter work, mainly sewing the uppers or “closing” and as trade expanded more, the lighter machines for this could be used in the home and “outdoor” work was once again introduced.

Some of the local factory owners took their employees on “annual outings” to a neighbouring village where they would be served tea and enjoy the sights of another place. With further expansion, so the factory owners organised more adventurous trips for their employees. In the mid 1940s John White took four trains carrying all his employees to London. He also gave them a packed lunch and a booklet with a map to tell them something about the capital city and organised an entertainment for them, at one of the theatres. The boom years for the trade were in the mid 1900s, but then foreign imports started to come, at first from Italy, then from the eastern countries and gradually one by one, the factories were closed down. By 1990 the majority had gone and today there are just four companies still shoemaking in our town. (2007)

Extract from an article John Cave & Sons Expansion The Rushden Echo, 11th March 1898

... Mr. Daniel Sharp, aged 79, who was the first shoe-manufacturer in Rushden, and for whom Mr. John Cave used to work before starting in business for himself. Mr. Sharp made the first rivetted shoe in Rushden.

|

Extract from an article in 1940 about Mr George Shaw - basket-maker

........ when Army boots were sent away in hampers. In the last war, however, manufacturers changed to boxes, and the hampers have not been used since. However “skeps” are still very largely used in various departments of boot and shoe factories, while chaff carriers for farmers are another particularly good line.

|

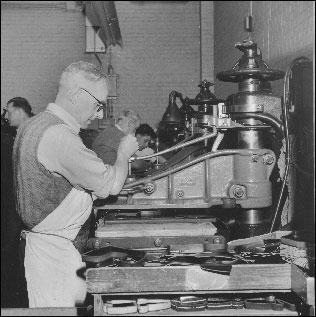

| This picture was taken at John White's Higham Ferrers factory in 1952. Geoff Ashby is taking a cup of tea from Mrs E Freeman, and he is wearing an apron to protect his midriff whilst working at his bench. These aprons were usually self-made, with button holes cut for the straps to hold it in place, one round the neck, and one around the waist. |

|

a shoemakers workshop

|