|

|||||||||||||||||||||||||||||

| From an interview with Peter Danby by Rae Drage 2007. Transcribed by Jacky Lawrence | |||||||||||||||||||||||||||||

|

The Co-op Fire Brigade

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

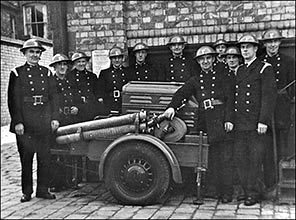

The Co-op factory was situated on the corner of Portland Road and Rectory Road in Rushden, it manufactured all kinds of footwear, gents’ footwear. The company had its own fire brigade and I joined it in 1957. Basically the idea of the Co-op fire brigade was to have fire prevention more so than fire fighting, it was for fire prevention within all its factories. The average number of firemen at each factory was between twelve and fifteen. We had a maximum of twelve at Rushden. It had nine firemen, a fire engineer, a second officer and a first officer.

We could work off mains water if we wanted but we had our own underground water tank. It was situated in the centre of the building and it was topped up by rainwater. That tank held forty five thousand gallons of water, very, very handed if you needed it. It was known to the County Brigades that we had that water and it had been used on more than one occasion. The factory was also defended by an overhead sprinkler system, the sprinklers were mains fed. If you had a fire the fusable link on the sprinkler head would melt, would let the water come out and it would actually fight the fire for you if you were not on the premises when the fire happened.

This did happen to us one night. We had quite a bad fire within the factory, the sprinklers all went off, nobody answered the bell at quarter to two in the morning, by the time they did decide to answer it we had got one almighty flooding at the factory, an almighty flood it took an awful long time to clear up. The fire happened on the night of the 28th and 29th of August 1968 and we do know that this was caused by smoking in the factory. What happened was we had consultants in the factory trying to get the factory to work more efficiently and somehow a truck load of rubbish which should have been taken out at night was not taken out and somebody who was in the factory quite late at night discarded a cigarette end in it. It smouldered and got on fire, it was in an upstairs room and it just blazed up, set the sprinkler system going and the rest of the story is quite well known. The sprinklers went off, we had eight heads go off in all and by the time we got there admittedly the fire was out, as good as out, but we had an enormous amount of water about. It had gone from upstairs, downstairs and into the basement as well, quite a mess. Just through somebody smoking who shouldn’t.

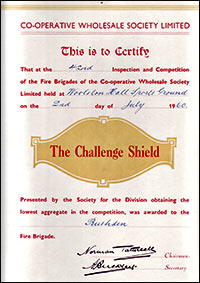

The only reason it is in the museum is because I was the last person who’d won that shield. After then the Co-op decided that they no longer wished to insure their own premises so therefore they did away with the fire brigades there and they had the premises insured by the Sun Alliance group. The Sun Alliance did retain us as a team of people who could look after the place from fire prevention point of view but the Co-op actually finished lock, stock and barrel with the fire brigades in I think it was about 1970. If you look on the shield when it was last won that will tell you when we last finished. The employees, they used to have a dinner and dance every Christmas, most of the time I think years ago it used to be in the Co-op hall in Rushden but in the latter years that I remember it was at the Windmill Club in Rushden. But when you used to be out on fire brigade duty and competitions prizes was issued for first second and third places. This would be bed linen, crockery, cutlery. All good household stuff that you needed. Small articles of furniture like coffee tables yes we won quite a few of those. When I first got married I didn’t buy hardly any bed linen at all. And towels, it was all good quality stuff. All Co-op, yes all Co-op. During competition time we did get time off to go out doing a little bit of training and they used to come down from Manchester to check that we were doing things right because you had three drills. A three men, a four men and a one man and you had to do those drills to the correct way of doing it and they used to come down to check prior to going to the competitions that you was doing them right 'cos many ways you could cheat but you was not allowed to.

When the factory was running down we stopped the training programmes. We stopped obviously competition work but we were not prepared to leave the place in the lurch and just think 'don’t bother anymore' because at the end of the day we all earned a living there and you just can’t walk out on a place like that. We all earned a living there. To the day that we actually left the place when they closed it we still looked after the place. Admittedly there was less of us because people was gradually made redundant as they closed the place down but we still stuck it out right up to the very end. I was never wanting to see it go. We didn’t want to see it burn down. We was lucky I mean as I say there was more fire prevention went on there than fighting. We did used to have a number of incidents in the factory which was basically caused by the dust that used to come off the shoes when they was scouring them or roughing the bottoms. It created a lot of dust, you’d strike a little bit of grindery which was the nails and the tacks and stuff from the bottom and it would set the whole of the trunking system on fire all the way through the factory. This was fanned; the dust used to be pulled off the machines by a fifty horse power fan and with a little spark in the right place and a fifty horse power fan blowing it, it didn’t take long for it to have nice little fire that would go right the way through the factory. It was all contained in the trunking system but it was an awful job to put it out, an awful job to put it out. But we used to manage it quite well. The main part of the factory was in Portland Road downstairs ground floor and first floor. The front was offices, all offices but they had a basement as well. They had the basement, ground floor, first floor, second floor. It was a big building as I say it was seventy seven thousand square feet and that is big, quite big, yes. I think it was the biggest factory in Rushden, I think it was. I could stand to be corrected on it but I don’t think I'm wrong.

Return to the CWS Introduction |

|||||||||||||||||||||||||||||