|

The organisation was tightened up early in 1940 by the centralisation of the control of the whole of the business, from the purchase of raw materials right down to the selling of finished boots and shoes.

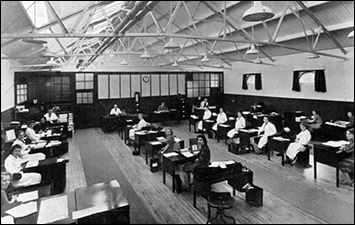

This centralisation of control, with the consequent transfer of the entire office staff to a well-equipped building in Rushden, now known as Imperial House, has facilitated the export side of Bignells, and the requirements of the overseas markets can be more easily assessed by the facilities afforded for statistical and market research.

Working from Rushden, Mr. W. G. Johnson, who is in charge of our export department, is—by daily contact with the home managers— kept fully informed of all new developments and the proportion of our manufacturing plant which can be allocated to work on overseas orders.

Agencies have been set up or marketing arrangements concluded to cover the whole of our African possessions, Canada and the West Indies. Outside the Empire, Bignells is at present building up a satisfactory trade with the United States of America.

|

|

|

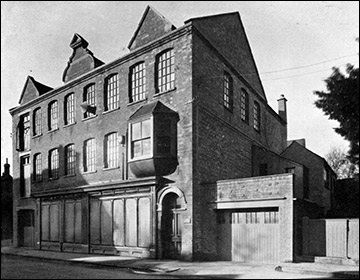

Imperial House. From these Rushden Offices, completed in 1940, the whole organisation is managed.

|

Staff from London brought to Rushden make it possible for selling and manufacturing to work in close co-operation.

|

It would not have been possible to build up Bignells to the position which it enjoys in the boot trade today without the loyal co-operation of our 1,200 workpeople.

Their Welfare, in the home as well as the factories, is the constant concern of the management.

Canteens and other facilities are available for our factory operatives and office staffs. Recently, in furtherance of the board's policy of providing every possible amenity for the comfort of our employees, a hostel was opened for those young people who have left their own homes to work in our factories.

This hostel is furnished and run in such a way as to provide a homely atmosphere and comradeship, which would be impossible of achievement if the youth so accommodated were left to find their own lodgings.

Moreover, it has to some small extent helped to solve one of our chief difficulties—the recruitment of young labour.

Consolidation of our manufacturing and financial resources has already brought considerable benefit to the company.

In war-time, Bignells, like many similar concerns, has made substantial payments to the Exchequer by way of taxation.

Benefits which should now be accruing to shareholders as a result of earlier absorption of profits into the business are now going to meet the demands for heavy taxation. Increased trading profits have, however, amply justified the policy of the directors in conserving resources and building up a large business.

In the belief that the extra contributions in taxation which we are now called upon to make are helping to secure victory and relieve future generations of the onus of bearing all the cost of war, the company gladly plays its part in war economy. Shareholders know, however, that when relief from the present burden of taxation comes, they will reap their reward for the sacrifices they have had to make while the company was being built up.

Bignells' organisation is second to none in the British footwear industry. It has been built up by the sacrifices made by our shareholders in foregoing dividends and by the devotion to duty of our workpeople.

Those sacrifices and that devotion have amply justified the confidence with which Mr. Arthur J. Bignell and his late son, Mr. Eric W. Bignell, started this enterprise.

|

|

|

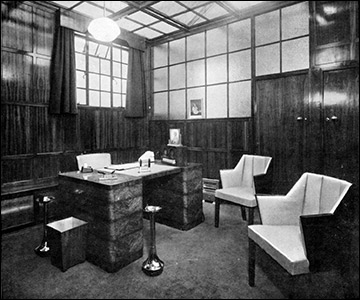

The Managing Director's Room

|

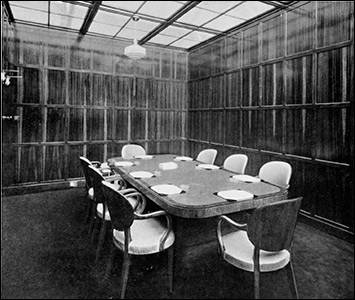

The Board Room

|

|

The directors are satisfied that the confidence which shareholders, workpeople and customers have placed in Bignells augurs well for the future trading of the company.

|

|

Kettering

|

The staff from our London office have been brought to Rushden making it possible for the selling and manufacturing sides to work in close co-operation.

When the decision was made to re-organise the company, control of all branches of Bignells was centred in the main office at Rushden. Picture shows the Managing Director's room, from which all important decisions affecting the company's production are issued.

Oak-panelled Board Room at the new Rushden Head Offices, which were completed in 1940. The former London Office is now used as a showroom only.

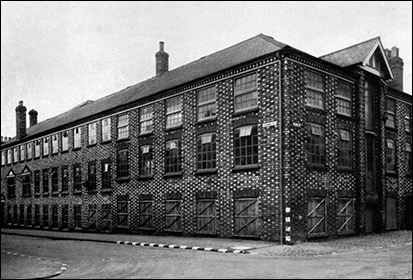

First headquarters and manufacturing unit of Norton and Bignell Ltd., was at Kettering. Producing to capacity, this factory can turn out 15,000 pairs of staple welted boots and shoes weekly. Production before Bignells took over was 3,600 pairs a week.

The Popular Boot Company of Raunds was taken over by Bignells in 1937. This factory now specialises in the production of medium grade children’s girls’ and youths’ footwear, with either leather or rubber soles and heels.

|

|

|

Wellingborough

|

Raunds

|

One of the two factories formerly owned by A. W. Gilbert & Sons, at Wellingborough was acquired by Bignells before the public flotation of the company in 1937. Under Bignells' control production was stepped up from 4,000 to 6,500 pairs a week.

The other factory acquired on amalgamation with Messrs. A. W. Gilbert & Sons, was in York Road, Rushden.

|

|

|

Cunnnington's Factory - corner of Crabb Street and Park Road

|

The factory in York Road, Rushden

|

Since Bignells acquired the factory from Messrs. Cunnington, production has been trebled to 7,500 pairs a week. The factory specialises in Goodyear Welted shoes, and is equipped with some of the most up-to-date machinery in the industry.

OUR PRODUCTIONS

We illustrate in the following pages some of the standard models in regular production in our five main factories. These styles are made in all the usual materials by the standard methods and in various grades as follows :

| Crabb Street, Rushden |

Medium to high grade Goodyear |

| Wellingborough |

Medium to best quality Staple Welted and Machine Sewn |

| Kettering |

Cheap Staple Welted for Home Trade and Export Markets |

| York Road, Rushden |

Produces heavy types of Boots by the Standard Screwed and Stitched method for Artisans |

| Raunds |

Produces a range of standard styles for Boys and Girls in good medium quality |

Under existing conditions of business it is not possible to print prices. Definite quotations depend on cost of materials and labour conditions at the time of ordering. They will be willingly supplied on enquiry and will always be found competitive.

|

|

|

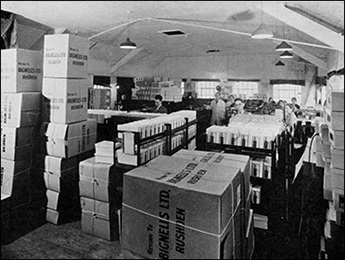

The despatch department at Rushden

|

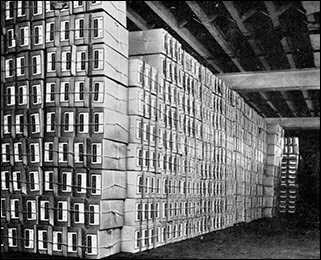

Part of a daily consignment of shoes ready for

despatch to customers in the United Kingdom.

|

We are, as far as possible, giving priority to delivery of orders for Export, and can obtain through Government permits certain upper materials which are not now available for Home Trade.

|

|

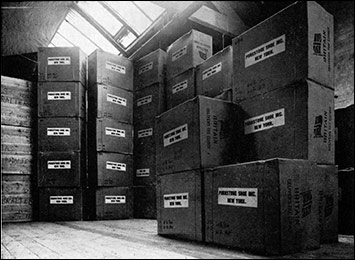

New York is the destination of this large consignment. Bignells have built up a lucrative Empire and foreign trade. Boots and shoes leave the factories daily for Africa, Canada, West Indies and the United States. Trade lost in German-occupied Europe had been more than made up elsewhere.

|

|

|

Two Clark & Perkins (W'boro) lorries loading a large order at Imperial House

|

|