Introduction

My friend, Mr Eric Fowell, being aware that the Gas Industry celebrated its 200 Anniversary in 2012 and knowing that my working life, (42 years), had been spent in various positions within the industry, encouraged me to write some memories for our Newsletter. [RDHS - 'Risdene Echo']

I hope my musings may be of some interest and will also serve as a record of the many changes I have seen in the Gas Industry during my lifetime, for posterity.

|

|

Part 1 - GAS - 'MARK 200'

The Two Hundredth Anniversary of Town Gas 1812-2012

By Graham Pack

It all began in 1812 with the ‘Gas Light and Coke Company’, the first company to set up a town gas works in London. Excited crowds of people flocked to witness the miracle of a flame burning without a wick, at the introduction of gas lighting. By 1819 parts of Nottingham were lit by gas, making it one of the earliest towns outside of London to have gas lighting in the streets.

As time progressed, Gas Works began to appear in towns large and small. Our first Gas Works, known locally as ‘The Gas House’, was built just north of the Old Walnut Tree, off the A6 in Higham Ferrers. I guess it must have dated from the 1840s as I have a record of an ancestor working there in 1851.

Rushden’s first Gas Works opened in 1874, on the corner of Duck Street and Church Street. In 1892 ‘The Rushden and Higham Ferrers Gas Co.’ was formed and opened new Gas Works in Shirley Road, Rushden. The final phase of gas making in Rushden was the replacement of the old horizontal retorts with a new vertical retort house, two years before the company was nationalised in 1949.

|

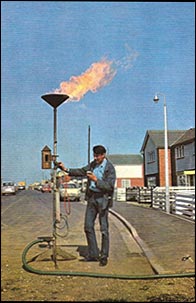

In radio contact with control, to report the arrival of natural gas to Rushden. At this purging point in Whitefriairs a change in flame colour indicates when natural gas has filled the supply system.

|

|

By the 1950s a network of gas mains linked our local towns – the foundations of our national grid system. This allowed the closing of small, uneconomic gas works. In East Northants alone gas works in Wollaston, Irthlingborough, Finedon, Raunds, Thrapston and Oundle were closed. These towns were now easily supplied from Northampton, Wellingborough, Rushden and Kettering – the remaining local gas works in production. Sadly their days were numbered as gas was already being imported from the Sahara to the Methane Terminal on Canvey Island. Two tankers, ‘The Methane Princess’ and ‘Progress’, would connect to their own jetty.

With the discovery of North Sea natural gas and the introduction of polyethylene distribution technology, gas could now be moved great distances under very high pressures. The Gas Holders, a part of our towns’ landscapes, became redundant. Small governors fitted to our customers’ gas meters reduce the pressure for domestic appliances.

Our region, ‘Emgas’, was the first to receive gas from the North Sea in 1967, and so started in Earls Barton, under the glare of TV cameras, a massive task of converting more than three million appliances over a seven year period.

During my working life I witnessed many developments within the industry. From having seen gas produced from coal at the start of my career, I am amazed gas is now imported by pipeline from many countries and the importation terminal at the Isle of Grain in Kent still receives shipments of gas from the Sahara.

|

|

Life of a Gas Man - Part 2

As a very nervous fifteen year old, I had risen early and prepared for my first day at work. The previous week, on the 6th February 1952, I had attended an interview with Mr Tom Watson, manager of the Rushden branch of the Gas Board, in his Shirley Road Office. In the presence of my father, I signed my indenture papers, committing me to a five year apprenticeship to become a qualified gas fitter.

This first morning, as I cycled past Higham Market Square, I glanced up at the weather vane atop the market cross to see if the wind direction was favourable for my journey – a habit I continued for many years. On reaching the crest of the hill into Rushden I could smell my destination. Unfortunately, gas escaping from the gas works during production contaminated the local area.

Turning left in Shirley Road and entering through the main gates I could see ahead, over the railway sidings, the Retort House, two large gas holders and a number of subsidiary buildings covering a very large area, all involved in the production of gas. On my immediate right a service road passed in front of a long, single storey office building. I discovered the main office occupied the first unit and incorporated the weighbridge and telephone exchange. A corridor ran the length of the building, providing access to the offices of the Manager (Secretary/Treasurer), Distribution Superintendent, Sales & Home Service, Meter Readers, Service Department and, finally, at the far end, the Gas Fitters Workshop.

On arrival I was greeted by Mr Frank Dickens, the foreman. He introduced his team of Gas Fitters, Senior Apprentices and Labourers – men I would be working with for the next five years, some became lifelong friends.

This being my first day, Mr Dickens handed me 5/- with the instruction to attend a medical at Dr Pain’s surgery in Park Road, a very brief affair – the doctor placed his hand on my heart, commented on the strength of the beat, asked for his fee and passed me fit. So began my working life in the gas industry.

………………………………

To become qualified I was required to study ‘Theory and Practical Gas Fitting’ two nights a week at Wellingborough Technical College. Also, I was released one day a week to attend classes ‘Theory and Practical Plumbing’, Mathematics and English at the college on St Georges Avenue, Northampton.

My first six months, before being given the opportunity of going onto the district as a fitter’s apprentice, were spent in work experience in various company departments. The first placement, gas production, was quite a culture shock for a lad just out of school.

The gas works were a hive of activity. Steam trains shunted wagons loaded with coal onto our sidings; a tractor then pushed a wagon, as required, onto the tipper at the base of the retort house. The wagon would be turned upside down, depositing its load of high grade coal, the size of sugar lumps, into the hopper below. The sound reminded me of a wave crashing on to a shingle beach.

The Retort House, the second tallest building after the church in Rushden, was an amazing place of appalling heat, dust, grime and smell. I could not believe men were expected to work in such dreadful conditions, but I was about to experience them first hand as I shadowed Mr Frank Fowell, works engineer. The lift regularly failed, caused by dust collecting in the relay switches. To gain access to the lift controls, housed in a unit on the roof of the Retort House, required a climb of three floors. Stairs and floors were constructed from expanded open metal sheets. Looking down you could see the stokers working in the basement far below. The final staircase led out onto the roof and our destination, exposed to the elements - I don’t remember any safety rails. We had a superb view looking over Rushden, but I hate heights and prayed we would make a quick repair and return to terra firma.

|

|

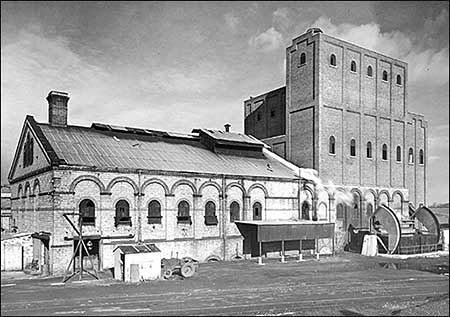

The old 1892 horizontal retort house, on the right the new vertical retort house with the wagon tipper visible at its base.

|

|

Some of the stokers, ex-navy men, seemed to revel in the intense heat of the gas ovens. Adjoining the gas ovens stood two Lancashire Boilers. Using waste heat from the ovens they produced steam which was piped around the site. I can remember once seeing steam used to free frozen coal from a wagon, so allowing it to drop into the hopper.

The large quantities of coke produced would be poured through screens to select a standard size, preferred by the coal merchants, then into storage hoppers and cooled ready for sale. The remaining coke fell into a 4’ wide mobile hopper. This, in turn, fed coke onto a conveyor belt beneath and removed the coke to storage facilities outside. The complete unit – hopper and conveyor – ran on a small railway track mounted on wooden sleepers. The wood used, I discovered to my surprise, was mahogany, used for its resilience to the coal and coke slurry that occasionally washed across the floor.

The gas, meanwhile, first passed through the condensers, which removed the tar and ammonia, then on into the purifiers, to remove sulphur. Finally, the gas, now cleaned of impurities, entered the booster. This machine pushed the gas into the gas holders. The gas, now stored, was ready to supply to our customers.

The purifiers were two filter beds, the size of a tennis court, approximately five to six feet deep, filled with oxide of iron. Periodically, the spent filter material required replacing. To facilitate access the purifier selected would be shut down and the cast-iron top panels lifted away, allowing labourers, armed with picks and shovels, to climb down onto the waste material and dig it out by hand. For safety reasons their hand tools were made of bronze. The smell during this exercise spread far and wide over Rushden.

Patients suffering chest problems would visit the filter beds to breathe in the sulphur fumes, although I preferred the smell of tar to ease my chest infections.

|

|

The blacksmith’s workshop and the two gas holders

|

|

My next placement was the Blacksmith's. The smithy rang with the sound of hammer on anvil. I watched, fascinated, as Joe Bollard, the blacksmith worked at his forge.

My most enjoyable time was spent accompanying the electricians. One of their weekly tasks required starting up two large gas engines. These turned the emergence turbines should the town electrical supply fail. The engines, housed in their own modern building, had flywheels approximately six feet in diameter. These required turning with a metal bar into the correct firing position, then turning on the gas, they quietly came to life. On reaching full speed the time had come to test the turbines. Their controls were housed in a glass protected compartment built into the corner of the main room. As the turbines began to turn, blue flashes of electricity danced and crackled over the control panel in a dramatic lightning display. The engineers bragged that the power produced could supply all Rushden, but I had my doubts.

The laboratory building stood north of the power house. Here two chemists worked, testing and controlling the quality of the gas and the various by-products. Just beyond the lab, stood a Heath Robinson type of machine, mounted on a large concrete base. It consisted of a cylindrical tank standing some eighteen feet high and twelve feet in diameter, surrounded by a tangle of pipes, valves and controls. I was informed this strange unit, in an emergency, could produce gas from oil should the coal supply be interrupted.

During my short time spent around the gas works I also met the resident bricklayer, carrying out general maintenance, and the painter; one of his jobs required colour coding the multitude of pipes and cables that ran around the site.

As I crossed back over the railway lines, that marked a distinct boundary between gas production and my next placing, the sales and service departments, I little realised that all I had seen and experienced over the past month would vanish in the next decade as a result of the introduction of natural gas.

|

|

Life of A Gas Man - Part 3

In my last article, as an aspiring apprentice gas fitter, I described how coal gas was produced in the Rushden Gas Works. Knowledge gained over the next five months, in the Sales and Service Departments, would prove an invaluable help in the years to come.

The general office overlooked the main gates and weighbridge. Receiving a warm welcome from the office girls, I soon found myself grappling with wires, plugs and winding handle, as I mastered the company’s telephone exchange.

The weighbridge’s 5’ long calibrated brass balancing bar and small sliding counter weight - used to obtain the final reading - were no problem.

During my first week in the office, I met the smartly dressed ‘Telephone Lady’. She was a contractor who called weekly to clean and disinfect all the company’s telephones – very hygienic.

Office staff only worked a five day week. Saturday mornings were covered by apprentices, on a rota system. The Friday evening of my second week, as we prepared to go home, imagine my surprise on being handed the office keys, with instructions to open at 8.00am. The following morning, I arrived at 7.45am, assuming this would give plenty of time to prepare for the morning ahead, only to discover a queue of approximately a hundred men and boys, waiting patiently with their homemade carts, wheelbarrows, old prams, or anything on wheels able to carry home bags of coke. These were hard times, so cheap coke helped to supplement their coal supplies.

|

|

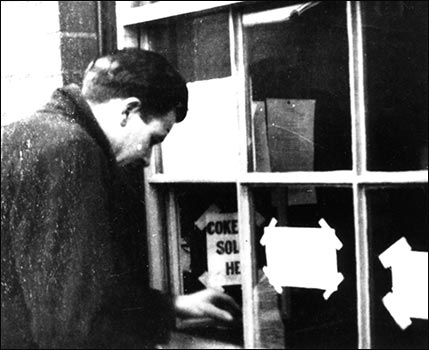

Buyer purchasing coke token at office window

|

|

|

Queue – waiting for yard men to weigh coke to fill each bag or sack

|

|

Opening the office as quickly as possible and seated at the counter under the window, overlooking the retort house, I opened a small hinged pane. Through this I could sell, for a few pence, tokens for ½ cwt. and 1 cwt. of coke and, occasionally, a token for a gallon of tar. Gas tar, thinned with paraffin, was a popular wood preservative.

My customers, armed with their tokens, now entered the works complex and formed another queue near the gas ovens, where yard men weighed the coke and filled their assortment of sacks and bags. During the morning the weighbridge was busy with coal merchants’ lorries, weighing the vehicles in and again on departure, and issuing an invoice for the weight of coke collected.

‘Breeze’ is another product of the gas ovens. Coke, when discharged from the ovens, is red hot and very crumbly. By the time the coke has been graded and stored a considerable amount of debris, consisting of small pieces of coke, dust and ash, is left. Being too dense to burn in a coke boiler or on an open fire, it was considered a waste material, until E. W. Braybrook Ltd, Coal & Builders' Merchants of Higham Ferrers, opened a company in Higham Lane to manufacture Breeze Blocks, for use in the building industry. These proved very popular. I remember all the internal walls of the houses on the Windsor Road Estate are of local breeze block construction.

My next assignment was the Stores, a modern steel framed building, holding a vast stock of pipes, fittings in many sizes, gas meters and appliances including: gas cookers, fires, refrigerators, wash boilers, early washing machines (fitted with a paddle you turned by hand and a small fold down mangle), gas rings, gas irons and pokers were also stocked. I don’t remember any central heating boilers; the Ascot instantaneous multipoint water heater was a popular way of providing hot water around a home.

|

|

Mr Frank Dickens & Mr Sidney Miles prepare an

Ascot Water Heater and a Cooker for delivery

|

|

Mr Bob Knight, in charge of the Stores, handed me a booklet, published by His Majesty’s Government, explaining the use of code numbers to control the movement of stock in an army stores. Bob had introduced the system into his stores and expected me to memorise them.

|

|

Model of a gas cooker

with 50p piece

|

|

Mr Bert Whitby, stores assistant, was a kindly man and as strong as an ox. Customers entering the stores and approaching the counter were greeted to the sight of a flat cap floating in a cloud of cigarette smoke. Bert was a chain smoking dwarf, just able to see over the counter. His hobby was making miniature copies of the gas appliances he handled every day. We became friends and he gave me a model of a gas cooker, about 4’’ high. The taps turn, the top folds down and the oven door opens, allowing the shelves to slide out – a much prized gift.

A World War II Nissen Hut completed the range or buildings backing on to Shirley Road, purchased from Sharnbrook Camp in 1951 by the Sports & Social Club, to provide a room for social activities, such as table tennis, skittles, darts and card games etc. The club room was also the home base of the cricket and darts teams. Lawn tennis, another popular game, was played on Mr T Watson’s (Manager) tennis courts. A practise cricket pitch, east of the Retort House, close to the Rushden to Higham railway line, completed the sporting facilities.

Rushden in the 1950s was growing rapidly. The distribution department’s two teams of mains layers were hard pressed to keep up with demands to install gas mains and service pipes to individual plots ahead of building the estates new roads. At times a team could be called away urgently to repair a reported gas leak – heavy traffic or earth movement often caused the old gas mains system to leak.

|

My time visiting the company’s various departments was coming to an end. My final days were to be spent with a team of mains layers, led by Mr George Mead, called to repair a reported gas leak on a very busy road. Although in attendance as an observer only, George had decided to work me until I dropped. He instructed me in the use of the road breaker, (no ear defenders or mufflers on the machine). This large hand held tool, violently vibrating, drove a chisel into the road surface, breaking it into small pieces to be continually shovelled away by a labourer. Eventually, on reaching the gas mains, we discovered gas leaking from a collar joining two lengths of cast iron main. To complete a repair the joint was recorked with hemp, followed by ladles of molten lead poured into the joint and hammered home to seal the leak. When access is limited, (no room to pour molten lead), strands of lead wool are used instead, to fill the joints. I returned home in the evening exhausted, still shaking and with a ringing noise in my ears from my day’s experience.

The following morning the team returned to the site to refill the hole and reinstate the tarmac road surface. One labourer shovelled loose materials into the hole, while a second labourer played water from a hose pipe to consolidate it. Mr Mead, (to me, a most unpleasant man), eagerly explained the controls on the ramming machine, my next challenge. Standing chest high and wider than my body, I realised controlling it would be a problem. With a push of the handle it exploded, forcing down a large flat metal plate on its base, crushing stones and creating a solid base for the final tarmac repair. To passers-by, I must have looked a funny sight, as I fought the machine – a 6’ 2’’, 9 stone, 15-year-old had no chance against this monster. With every ignition the rammer lifted me off my feet; we were air born, machine and I together. I staggered home that evening, safe in the knowledge I had completed my introduction into the company’s many departments.

Come the morning I was off to Technical College.

|

|

|

Life of A Gas Man – The Final Chapter

Previously I have described my introduction into the gas industry, including my five year apprenticeship through which I gained City & Guilds qualifications in Gas Fitting and Plumbing. The time then arrived to be issued with a uniform, (cap, coat and overalls), a set of tools in a large leather tool bag and a carrier pedal cycle – my transport.

Poised ready to be let loose on our customers, I was first assigned to a gas fitter as his assistant, to gain experience. My mentor, Mr Geoff Andrews, was well known locally as Goal Keeper for Rushden Town Football Club. We visited customers’ homes to service and repair their gas appliances.

A few properties and all the streets in Rushden and Higham were still illuminated by gas. One of Geoff’s extra jobs was driving around the streets at night, in the company’s only van, to check the lights were working correctly, any faults found, to be rectified the following day.

|

|

A pull of a lever to release catch holding the lantern firm, followed by turning a handle to lower lantern suspended on a cable, facilitate cleaning and replacing mantels etc.

|

|

Large gas lanterns suspended from gantries over the centre of the A6 road through both towns and along Wellingborough Road, proved difficult to lower owing to passing traffic. I remember on one occasion, near the Oakley Arms public house, a Birch's Bus collided with a half lowered gas lantern.

I had never imagined attending scenes of death and destruction, but I soon discovered this was part of a gas fitter’s job.

Very early in my career Geoff and I were instructed to go urgently to an address in Higham Road, Rushden where a well-known local businessman had committed suicide. I remained outside the property while Geoff, accompanied by a Police Officer, entered the kitchen. The task of the gas fitter required rendering the area safe by turning off the gas and ventilating the building, and at a later date he would attend the inquest as a witness. On leaving the sad scene, Geoff described how the gentleman had prepared himself by laying on cushions and pillows, before placing his head in the gas oven.

Some months later, when answering another urgent call to a fatality, we discovered a young man had died whilst taking a bath. A bird’s nest had blocked the ventilation flue of the gas geyser, causing poisonous fumes to spill into the bathroom. Thankfully serious incidents were very rare. I can only recall two explosions of note. The first was caused accidentally by lorries entering and leaving a warehouse in Wentworth Road, Rushden. Deep winter frost made the road surface very hard and the weight of the lorries fractured the cast-iron gas main under the road, allowing the escaping gas to enter the sewer system. Meanwhile, in a house on the corner of Moor Road and Wentworth Road, a man was sitting on the toilet in his first floor bathroom. Unfortunately, a bird’s nest had blocked the toilet’s vent pipe. The build-up of gas and the subsequent explosion caused considerable damage to the rear of the property, including the bathroom, and the gentleman was rushed to hospital with very serious injuries.

In the second incident, a customer rang the Office to report her new gas cooker had exploded. On entering her kitchen it became obvious what had occurred. Looking up I could see embedded in the ceiling, surrounded by chunks of meat and a colourful display of mixed vegetables, the lid of a pressure cooker. It had exploded with such force; the main body of the cooking vessel had pushed down and reduced her new cooker to half its original height. After sealing off the gas supply, I recommended she contact her house insurers.

When I joined the company approximately 70% of our customers paid for their gas through prepayment meters. A programme to change the penny coin mechanisms to accept shillings was nearing completion. For a time this caused a shortage of shillings in the local shops. Word spread fast when the Meter Collectors were in the area. Excited families would gather in the kitchen as the meter’s cash box was emptied with a crash on to the table. After the collector had counted and bagged the amount to cover gas used, the remaining cash was given back to a very happy customer, as rebate. On the odd occasion when the money in the meter’s cash box failed to cover the cost of the gas consumed, (so no rebate), the collector would leave the customer’s home as quickly as possible.

|

|

Meter collectors bring in their takings c.1940s

|

|

The collector’s large leather bag soon filled with heavy bags of coins. As he progressed from house to house he would empty the bag into a box shaped hand cart with a lockable lid that an assistant pulled along the street.

At the end of the day's collecting, the hand cart was pulled to Rushden Town Centre, passing along a lane off Victoria Road, to the rear of the Gas Showrooms, (110 High Street), where a cashier counted the day’s takings, before securing the cash in a large safe overnight, ready for banking the following morning.

When on showroom duties, I dreaded the time the quarterly gas accounts were sent out. Most were paid in cash; the queue of waiting customers sometimes stretched out of the showroom and along the pavement outside; each receipt was hand written in a receipt book; the top copy required gluing onto the account and finally signing over a stamp – a very laborious procedure. Six times a week, at the close of trading, the books had to balance, sometimes requiring one or two recounts, then the day’s takings - a considerable amount - was locked in a leather satchel and carried the length of the High Street to be deposited in the night safe of the National Westminster Bank.

|

|

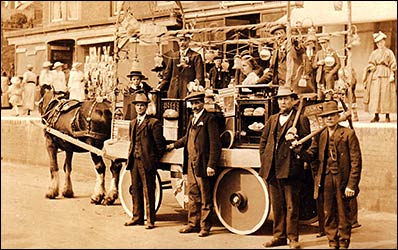

An early Carnival Float displays Gas Lights, Cooker and Fire accompanied by members of staff c1917

|

|

Eight local showrooms competed annually for the best window display award. I recall some ingenious ideas including a seaside scene and a chef’s kitchen with live cooking demonstrations. The carnival float entry also challenged the staff to provide a good display of modern gas appliances.

Many customers purchased their cooker by signing a Hire Purchase agreement, to pay a set monthly amount until the loan was repaid. Some failed to keep up the repayments so, after many warnings, I would find myself assisting a bailiff to recover the appliance. Being aware a visit was imminent, in answer to our knock a voice would ask, ‘Who is there?’ The bailiff replied, ‘Social Services.’ The door would open and we were in – it worked every time.

Since 1812 lead pipes had been used to provide a gas supply within properties. Being a soft, heavy metal the pipes sagged over time, creating gas leaks from soldered joints and appliance connections. To expedite a repair I used a small lamp, 5’’ high, and 1½’’ in diameter, with a ¾’’ wick, a rubber tube and a mouthpiece through which to blow, filled with mentholated spirits. The blow lamp was ideal for delicate soldering. One fault, when tipped at an angle, meths would leak out. Many times I have looked down to see a pool of shimmering blue flames around my feet. One drop on net curtains and they vanish like magic.

Lead pipes were last used in the 1950s Tollbar Estate houses. For the next decade, iron piping became the material to use, but rather labour intensive, as each length of pipe required cutting using a hacksaw and threading with a set of stocks and dies. Eventually the versatile copper pipes became available.

A tip for a job well done came in many forms. I always felt uncomfortable accepting money from my elderly customers; they could ill afford to give a tip on top of the repair charge. On the other hand, in the early days of my career, after working in Mr Jones’ Banana Ripening House, a hand of bananas was a very welcome gift, as were bars of chocolate. One lady always had two books for my children ready, when I called annually on a maintenance visit. Trays of eggs were a challenge on my bike, but I always got them home. Unique to Raunds and Stanwick were turkey drumsticks, rejected from the Sunday roast dinner. I was only too pleased to add them to my lunch box. Locally turkey had replaced roast beef, thanks to Stanwick Turkey Farm, where many local people found employment.

After 20 years as a gas fitter I set aside my bag of tools and took up a position in management. I still remember certain addresses fitters had to visit in pairs, for their own safety – guards with dogs patrolling the gardens of a house owned by a diamond dealer and the lady in Alfred Street with her painted front door step – you stood on it at your peril.

Over the years I must have drunk hundreds of cups of tea, in various flavours and colours, but chai, brewed by my customers in Leicester, who placed the ingredients – tea, milk, sugar, water – in a saucepan and boiled, that really challenged my taste buds.

With the introduction of non-toxic natural gas, thankfully no more suicides and being clear of impurities, maintenance of gas appliances has reduced to a minimum combustion flue test. Gone are the Gas Works, Showrooms, Meter Collectors and hundreds of supporting staff. Customers today with prepayment meters purchase gas 'swipe cards' from their local shop.

The gas industry I joined 62 years ago is just a memory.

|

|