He saw many changes in the shoe trade, one of them being the abandonment of the system of overhead shafts, pulleys and belts to drive the machines and the replacement by individual electric motors. At one time the factories nearly all had their gas engine to drive the shafts and these gradually disappeared. Just as well as the old system was dangerous, it was not unknown, if a machine seized, for it to be pulled into the air by its belt. The BU machines weren’t actually bolted to the factory floor as this would have made them fixtures and fittings of the factory and the BU would have lost ownership of them. Instead they were held in place by metal plates bolted to the floor which allowed them to be leased without loss to the BU if the shoe firm went bankrupt or changed hands.

|

|

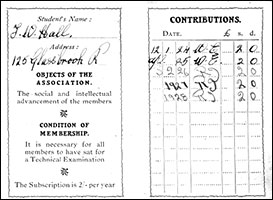

Membership card

|

|

He was also involved in installing machines in what was to be a major change in the industry, the introduction of moulded footwear. Instead of the many operations around the factory to produce a show the upper on its last was placed in a machine with a plastic sole and heel and they were bonded together. One man could operate several machines together and was therefore producing the same number of shoes as the many men around the factory carrying out their individual operations. I think the first factory to embrace this method of working was the Newton Road factory of John White which mass produced shoes constructed in this way for Marks & Spencers.

| The BU rewarded its employees for long service by membership of their “Quarter Century Club” and membership was open to all from managers to floor sweepers. They were treated to an Annual Dinner in Leicester and sported a triangular lapel badge. |

|

|

|

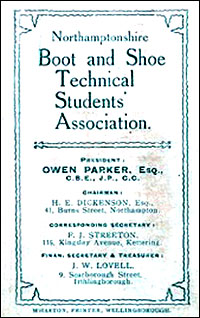

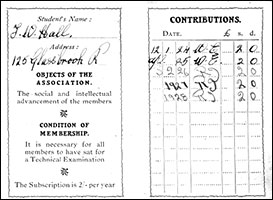

Club members' card

|

|

|