Off with the blazers and on with aprons is the routine which marks a change of lessons at the Rushden Boot and Shoe School.

It runs on lines something like those laid down by Mr. Squeers, who first taught his boys to spell the word “horse” and then sent them out to groom the animal.

Here, in the classroom, the boys are told what goes on in shoe factories, and then they go into the school workshops and practise the different stages of manufacture.

The school was opened in 1928, and today is equipped with all the machinery of a modern factory. Its full-timers, in the Secondary Technical School, are boys who are bound for one or another of the local shoe factories when they reach school-leaving age. They came from the secondary modern schools in Rushden, Wellingborough, Raunds and Irthlingborough at the age of 13, and along with grammar and maths they learn their trade.

|

|

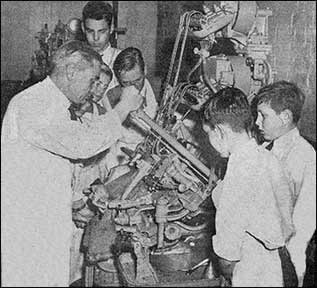

The Rex I.P.O. – the pulling-over machine – holds the interest of the first year day school as Mr T C Major demonstrates its powers. The boys have not yet been allowed to “have a go” themselves as they only began the course two months ago, and this will come later.

|

Part-timers – girls from the local factories who are released from their own closing rooms two afternoons a week to learn a few more of the tricks of the trade in the shoe school closing room, gather round as instructress Mrs L Tandy shows them how the beading machine folds in the edges of the leather.

|

The factory school is viewed with enthusiasm by these 13-year-olds. The whirring machinery and businesslike tools are a welcome break from exercise books. And the boys like to be using their hands.

Clicking

|

|

In the clicking room, two of the second year day school class look business-like in shirt sleeves and white aprons. Several of the boys in this class had already decided that they are going to stick to the clicking room when they start work next year.

|

Their first task is to learn the old cobbler’s job; they find out a great deal about a shoe in doing the job by hand, before going on to master the machinery.

In the clicking room, they learn pattern cutting, and with the job of clicking, the quality of different segments of skins, and how to cut them economically. Skin patterns decorating the walls, which at first glance look like trophies of a hunting expedition, are there to point out the difference between belly and shoulder.

Racks of shoes in various stages of completion bear witness to the work that goes on in the Making and Finishing Room, where the boys practice on some £10,000 worth of machinery. They begin with “exercise work” using odd scraps of leather, and eventually graduate to making slippers and walking shoes, which are sold.

In the laboratory they learn the science of materials, and the processes of testing.

They are joined in the afternoons by beginners from the factories, who consider it a “change from the factory.”

Girls from the closing rooms, learning machining as a whole instead of the particular job they do for a living, find “current affairs” lectures the most interesting. They are released two afternoons a week to take the course.

Now, just to complete the training, trade unionism is being added to the curriculum.

|