|

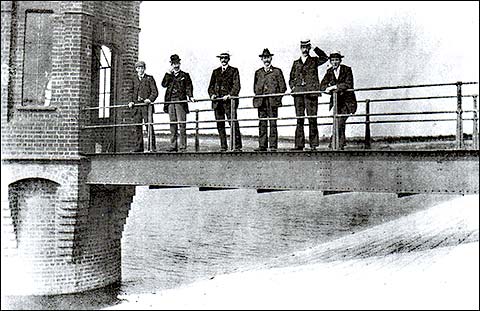

The Bill received the Royal Assent at the end of June and the two town Councils set about choosing their representatives for the Joint Board which would consist of six representatives of Rushden and three of Higham Ferrers. The newly elected members of the Board held their first meeting in July in the Higham Ferrers Town Hall to appoint the officers. Mr George Denton was elected to be the first Chairman and Mr Owen Parker the Vice-Chairman. Mr G S Mason was appointed clerk to the Board with Mr F J Simpson as deputy clerk, and Mr Middleton as the engineer. Plans were received showing the amount of land required for the works at Sywell, and the Clerk was instructed to serve notices for the purchase upon the owners and tenants. The clerk was also instructed to advertise for tenders for the construction of the proposed reservoir at Sywell.

At the monthly meeting of the Board in August Mr W B Madin was appointed as surveyor to the Board.

In September, the members met with Mr Middleton to review the tenders received. Ultimately the tender of Mr A E Nunn, of Tenterden, Kent, was accepted, the amount being £57,072 2s 0d [£57,072.10].

£8,500 was paid to Lord Overstone’s trustees for the 56 acres taken from them. Acquisition of the remaining land at Sywell did not proceed smoothly and by December the Board was aware that they would have to resort to the tedious process of arbitration. The secretary to the Board made an application at the Wellingborough Police Court for the appointment of a surveyor to enable powers under the Lands Clauses Acts to be instigated. However, before that hearing took place, satisfactory compensation agreements had been reached with Major-General Sotheby with a payment of £2,000 for about 37 acres of land, and a similar amount to Mr Stockdale for 33 acres. A third agreement for £300 was settled with the trustees of Palmer’s Charity at Ecton for a small piece of the charity lands, with a further payment of £25 as compensation to the tenant of that land.

Further progress was delayed as the Board was still obliged to go to the Magistrates for a decision on the compensation claimed by Messrs Brown and Son of Sywell for the disturbance of their tenancy of 60 acres of land. The advisors of the Board calculated that £350 would amply reimburse the tenants for any damage sustained, but the tenants’ calculations claimed £1,200. At the hearing Messrs Brown and Son were awarded £515 by the Court. The remaining compensation claims of Messrs Rickett and J H Gartside were referred to the Arbitrator to be dealt with at a later date, and the landowners’ arbitration would take place at the Surveyors’ Institute in London in April.

Work at Sywell began immediately and by March 1903 Mr Middleton reported that there were 38 men employed at the site at Sywell, and the average number at work on the service reservoir and laying the pipe-track was 100.

The claims by General Sotheby for £10,500 and by Mr Stockdale for £7,700 for the purchase of their land were heard over three days in London at the end of April. The awards announced about four weeks later were: General Southby £5,383 15s 0d; Mr H M Stockdale £4,648 7s 6d; Mr J H Gartside £274 8s 0d; Mr A J Rickett £292 17s 10d.

Rumours that when the reservoir was completed there would be a difficulty in finding sufficient water to fill it were dispelled when it was found that during a period of wet weather in May on just one day 12,500,000 gallons of water passed down the stream.

Since the commencement of the reservoir at the beginning of the year, considerable progress had been made in carrying out the undertaking. The preliminary task of clearing the ground and felling the timber had been completed by September and the work of excavating the bed of the reservoir was in full swing. In the vicinity of Sywell, upwards of 150 men were employed “digging out the bowels of the harmless earth,” and this was a significant boon to the depressed labour market being experienced at that time in the surrounding villages. Many of the workmen came from as far as Northampton and Wellingborough, entailing a daily walk of ten or twelve miles in addition to their day’s manual labour.

Mr Wilson, the head engineer, was in complete charge of the operations, assisted by Mr Parker.

On 23rd September 1903, representatives of the local press were invited to join members of the Water Board on a visit to the site at Sywell. A brake was supplied by Mr Sargent and conveyed the party of eleven to Sywell via Doddington and Earls Barton. They noted the evidence of the work’s progress at the roadside between those two villages where they saw the large pipes to be used for the water main for some distance along the road. The original mains pipes were eleven inches in diameter and were unique to the Higham Ferrers and Rushden Water Board. They were bolted together and ‘run lead sealed’ – lead wool being rammed into the joint and heated.

|

|

Members of the Higham Ferrers Labour Party

|

On their arrival at the site of the reservoir, the visitors’ attention was first taken by the ‘unclimbable’ iron fence which surrounded the site and then by the impression of the scale of the construction. They then saw the newly constructed filter beds but their attention was completely taken by the large number of men busily at work building the embankment across the valley. To the right, a gang of men was at work loading wagons with soil which were run down and tipped on the sides of the embankment. Others were cutting out the clay which, so fortunately for the progress of the work, was found in abundance. They had already produced a deep and wide pit simultaneously increasing the capacity of the reservoir. The clay was dragged to a point about the intended height of the embankment where it was broken up by machinery, and after being “kneaded” well together, it was sent in small slabs down a chute to the required place where it was placed in the trench and thoroughly trodden down by relays of men. This puddle wall of clay, some nine feet wide, ran along the centre of the embankment for its entire length.

The visiting party, having descended the inner side of the embankment and examined what would eventually be the bed of the reservoir, climbed back into the brake and returned to Higham Ferrers and Rushden, impressed with the progress being made.

Abnormal weather conditions during October seriously delayed progress of the work at Sywell. Unconfirmed stories reported that horses had had to be dug out from the unstable embankment on more than one occasion.

At the monthly meeting of the Joint Water Board in November, the engineer, Mr R E Middleton, reported that work had been delayed due to the continued wet weather and the embankment was so wet that it was impossible for horses to work on it. However progress had been made with the laying of the water main. On several days only a few men were at work, but the average number of men employed at the reservoir on the days when the full squad were working was about 115, and about 50 on the pipe-track. The rainfall for the month was 4.995 inches, and the water gauge in the Sywell stream showed an average flow of 2,515,600 gallons per day.

At the beginning of 1904, the engineer, Mr Middleton, forwarded a report of the progress of the works during 1903. He advised that the total quantity of puddle put into the trench was 2,143 cubic yards, and about 18,500 cubic yards of banking had been put into the bank, whilst nearly 750 cubic yards of large lump slag had been built into the main and cross slag drains in the bank. It was unfortunate that the bad weather had delayed progress on the embankment and estimated that the contractor had lost about two months’ time. The perimeter fencing to the site had been completed, as had the service reservoir on the Bedford Road which is of concrete construction with a metal hot-riveted tank lined with white glazed bricks and a capacity of 800,000 gallons of water.

By April, work was still far from satisfactory and the contractor was pressed to employ more men – the average number during the preceding four weeks had been about 110.

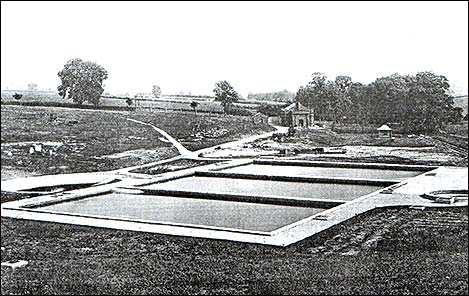

Mr Middleton reported in June that progress was fairly satisfactory. In addition to the work on the bank, the brickwork of the filter beds had been completed, and the pipes of the rising main had been laid from opposite the service reservoir to within about 50 feet of Rhyholme Bridge and from the bottom of Doddington Hill to within a few feet of the gate at the pumping station.

|

|

The Filter Beds

|

|

During the following month the tile drains were laid in the centre filter and the bottom layer of filtrate had been put into position. All progress was keenly marked by most of the inhabitants of Rushden, but none more so than those in the higher parts of the town where there was no water for several consecutive days. The buildings affected were mostly new and no wells existed. People had to beg water from their more fortunate neighbours and the Urban Council attempted to send the water carts round each day |

At Sywell, excavations in the west end of the puddle trench were almost completed during August, but as the bank was by now getting narrower the contractor had less room to work. Fair progress was still being made with the exception of the banking. The average number of men employed on the works was 200 with a further 12 working on the pipe-track.

Mr Middleton’s report to the September meeting of the Board stated that the excavation for the puddle trench at the reservoir had been completed, the total length being 1,154 feet. The average level of the bank had been raised to eight feet below the finished level and, given fine weather, it was hoped that the banking would be completed during the following month. Mr Wilson, the resident engineer at Sywell, attended the meeting and reported that a bad slip had been discovered in the centre of the embankment. Mr Middleton had been notified and was expected to return at once from abroad. The slip had occurred on the inner slope of the bank and steps were taken to remove the outer bank to a corresponding level in order to ease the thrust on the puddle and the slipped material. Mr Middleton was unable to identify the cause of the slip, but ordered that the inner slope of the bank should be decreased.

Six months later, in March 1905, work was almost complete in connection with the repairs to the portion of the embankment which had slipped. With the exception of the steel pipes over the river Nene, the rising main had been completed from the service reservoir to the entrance at the pumping station.

The embankment at the reservoir was brought up to the required height in July and the laying of concrete blocks on the face of the dam was begun. When the majority of this had been completed it enabled the valve to be shut down and a start made to impound water.

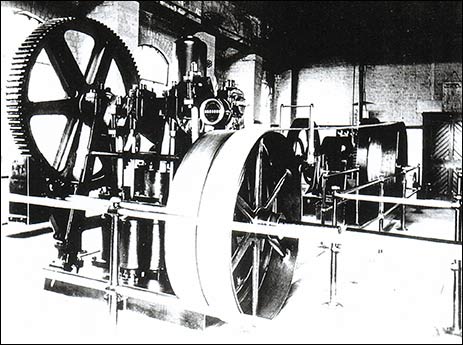

By October the rising main was completed as was the main from the clear water tank to the engine-house. The engines were almost finished and the water continued to rise steadily in the reservoir.

| In November the Board decided to dispense with the services of Mr Taylor, the resident engineer at the works. He asked for a testimonial and also for some recognition of extra night work from September 1904 to March 1905. It was decided to give Mr Taylor a testimonial and £5. The post of engineer at Sywell was advertised and in January 1906 was offered to Mr Spratt of Brackley Waterworks. By this time there were about 50,000,000 gallons in the reservoir and the surface area amounted to nearly 16 acres. |

|

|

The Pumping Engine

|

|

At the meeting of the Board in February, the committee was keen to commence testing in April. Mr Middleton asked to postpone using the supply for as long as possible as he preferred to get 150 million gallons in the reservoir before testing. The committee’s reason for testing during April was that nothing could be done in the way of connections with house property in Higham until the testing had been done, and that if it was carried out in April then the supply could come into operation at the beginning of July.

During March, one set of engine and pumps was ready and a short trial had been made, and the other set was almost finished. The water now covered a surface of 41½ acres. The following month the engines and pumps were run several times in order that the rising main might be filled and tested.

|

|

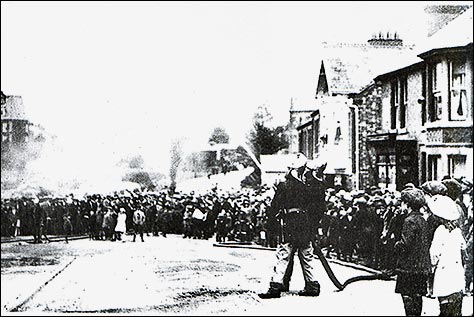

Testing the Water Pressure

|

|

By June the Rushden Fire Brigade had carried out a series of drills to test the pressure of water and an experiment near to the church demonstrated that a stream of water could easily be thrown over the church. |

|