|

||||||||||||

| Northamptonshire Advertiser, 4th December 1964 |

||||||||||||

|

Ferrafoam

|

||||||||||||

|

|

||||||||||||

|

||||||||||||

|

Rushden Firm is the Centre of a New Idea THE average man's heavy tweed overcoat can cost anything up to £20 and weigh anything over half a stone. But today, using a material which is produced in great quantities in Rushden, that same coat—to all intents and purposes — can be made at a greatly reduced price and at a fraction of the weight.

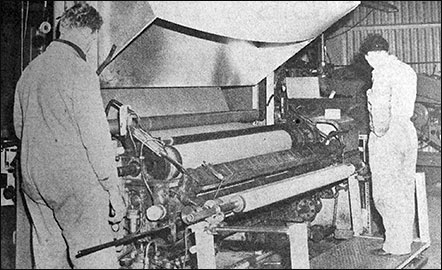

This new material—and it is new as far as the garment industry is concerned—is foam. Foam-backed wool, fur, nylon, silk . . you name it and the Ferrafoam division of W. W. Chamberlain and Sons Ltd., John Street, Rushden, will foam laminate it.

|

||||||||||||

And as "Rushden and Higham Ferrers made" means something in the boot and shoe industry, so the Ferrafoam stamp means something in the garment world. Mr. A. J. Chapman, director in charge of Ferrafoam, said: "This unit has been set up by standards laid down by one of the largest multiple stores in the country." Ferrafoam's main objective is to get the trade re-educated on the whole concept of foam laminated materials and away from some of the bad impressions created in the early days. At one time many fabrics were foamed just to sell. [Part of a longer article] |

||||||||||||